New manufacturing process for SiC power devices opens market to more competition

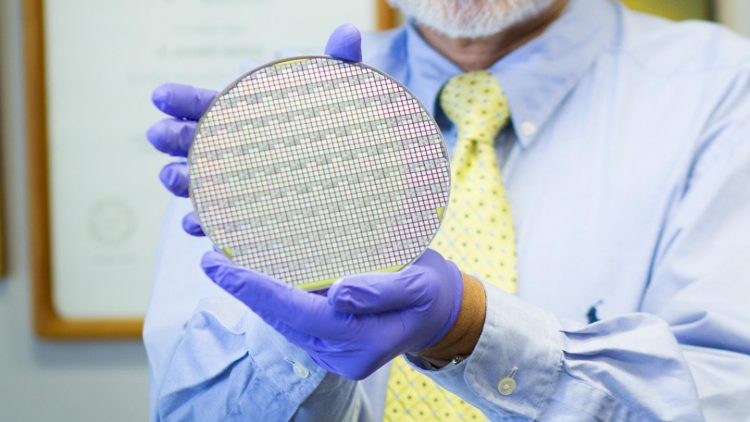

Silicon carbide power devices, like the one shown here, are more efficient than their silicon counterparts. Credit: NC State University

“PRESiCE will allow more companies to get into the SiC market, because they won't have to initially develop their own design and manufacturing process for power devices – an expensive, time-consuming engineering effort,” says Jay Baliga, Distinguished University Professor of Electrical and Computer Engineering at NC State and lead author of a paper on PRESiCE that will be presented later this month.

“The companies can instead use the PRESiCE technology to develop their own products. That's good for the companies, good for consumers, and good for U.S. manufacturing.”

Power devices consist of a diode and transistor, and are used to regulate the flow of power in electrical devices. For decades, electronics have used silicon-based power devices. In recent years, however, some companies have begun using SiC power devices, which have two key advantages.

First, SiC power devices are more efficient, because SiC transistors lose less power. Conventional silicon transistors lose 10 percent of their energy to waste heat. SiC transistors lose only 7 percent. This is not only more efficient, but means that product designers need to do less to address cooling for the devices.

Second, SiC devices can also switch at a higher frequency. That means electronics incorporating SiC devices can have smaller capacitors and inductors – allowing designers to create smaller, lighter electronic products.

But there's a problem.

Up to this point, companies that have developed manufacturing processes for creating SiC power devices have kept their processes proprietary – making it difficult for other companies to get into the field. This has limited the participation of other companies and kept the cost of SiC devices high.

The NC State researchers developed PRESiCE to address this bottleneck, with the goal of lowering the barrier of entry to the field for companies and increasing innovation.

The PRESiCE team worked with a Texas-based foundry called X-Fab to implement the manufacturing process and have now qualified it – showing that it has the high yield and tight statistical distribution of electrical properties for SiC power devices necessary to make them attractive to industry.

“If more companies get involved in manufacturing SiC power devices, it will increase the volume of production at the foundry, significantly driving down costs,” Baliga says.

Right now, SiC devices cost about five times more than silicon power devices.

“Our goal is to get it down to 1.5 times the cost of silicon devices,” Baliga says. “Hopefully that will begin the 'virtuous cycle': lower cost will lead to higher use; higher use leads to greater production volume; greater production volume further reduces cost, and so on. And consumers are getting a better, more energy-efficient product.”

The researchers have already licensed the PRESiCE process and chip design to one company, and are in talks with several others.

“I conceived the development of wide bandgap semiconductor (SiC) power devices in 1979 and have been promoting the technology for more than three decades,” Baliga says. “Now, I feel privileged to have created PRESiCE as the nation's technology for manufacturing SiC power devices to generate high-paying jobs in the U.S. We're optimistic that our technology can expedite the commercialization of SiC devices and contribute to a competitive manufacturing sector here in the U.S.,” Baliga says.

The paper, “PRESiCE: PRocess Engineered for manufacturing SiC Electronic-devices,” will be presented at the International Conference on Silicon Carbide and Related Materials, being held Sept. 17-22 in Washington, D.C. The paper is co-authored by W. Sung, now at State University of New York Polytechnic Institute; K. Han and J. Harmon, who are Ph.D. students at NC State; and A. Tucker and S. Syed, who are undergraduates at NC State.

###

The work was supported by PowerAmerica, the Department of Energy-funded manufacturing innovation institute that focuses on boosting manufacturing of wide bandgap semiconductor-based power electronics.

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…