Laser treatments yield smoother metal surfaces

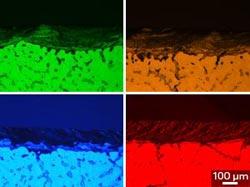

Optical microscope cross-sections of the alloy surface show that increases in laser beam overlap during processing reduces the number of small cracks (top left, 25% overlap; top right, 50%; bottom left, 75%; and bottom right, 90%). <br>Copyright : © 2013 Elsevier <br>

Ever since the Bronze Age, metals have been cast in different shapes for different applications. Smooth surfaces that are resistant to corrosion are crucial for many of the present-day uses of cast metals, ranging from bio-implants to automotive parts.

Yingchun Guan, from the A*STAR Singapore Institute of Manufacturing Technology (SIMTech) and her co-workers have shown how different laser-processing methods improve metal surfaces and protect them against corrosion1.

Laser processing involves scanning a high-intensity laser beam multiple times across the surface of a metal. Each scan by the laser beam ‘writes’ a track in the surface, which partially melts the metal. Consecutive tracks can overlap — the degree to which affects how well the melting caused by these tracks will smooth the surface of the metal. The scanning speed can also affect the surface melt.

Guan and co-workers investigated how different degrees of overlap between the tracks affect the surface properties of AZ91D — a common magnesium alloy. “AZ91D is the most widely used magnesium alloy for the production of high-volume components for the automotive, electronics and telecommunications industries,” Guan explains.

By examining cross-sections of AZ91D samples post-melt, the researchers found that the greater the degree of overlap between the tracks, the fewer the number of small cracks that developed during solidification (see image). According to Guan, this finding should be considered when processing metals destined for exposure to fluids, such as those that will be used in bio-implants.

The researchers also detected alterations in the alloy’s composition through changes in the degree of laser-track overlap. Melted magnesium evaporates more readily than aluminum, and as the degree of laser-track overlap increased, it changed the composition of the alloy — particularly in the larger areas of melt. Theoretical calculations by Guan and her co-workers described these kinetics accurately.

According to the team’s model, a greater level of overlap provided a greater amount of heat, which improved the convection of the metals within the molten liquid and yielded a more homogeneous surface. Electrochemical tests by the team also confirmed that the more homogeneous the surface of a material, the more resistant it was to corrosion.

The team’s approach, particularly the theoretical model, is applicable to assess laser processing of other alloys and compounds, Guan notes. As the surface structures affect not only the mechanical and chemical properties but also the electronic, thermal and optical parameters, these findings will be of relevance to metals used in a variety of applications.

The A*STAR-affiliated researchers contributing to this research are from the Singapore Institute of Manufacturing Technology

Reference

Guan, Y. C., Zhou, W., Li, Z. L. & Zheng, H. Y. Influence of overlapping tracks on microstructure evolution and corrosion behavior in laser-melt magnesium alloy. Materials & Design 52, 452–458 (2013).

http://www.sciencedirect.com/science/article/pii/S0261306913005074

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Why getting in touch with our ‘gerbil brain’ could help machines listen better

Macquarie University researchers have debunked a 75-year-old theory about how humans determine where sounds are coming from, and it could unlock the secret to creating a next generation of more…

Attosecond core-level spectroscopy reveals real-time molecular dynamics

Chemical reactions are complex mechanisms. Many different dynamical processes are involved, affecting both the electrons and the nucleus of the present atoms. Very often the strongly coupled electron and nuclear…

Free-forming organelles help plants adapt to climate change

Scientists uncover how plants “see” shades of light, temperature. Plants’ ability to sense light and temperature, and their ability to adapt to climate change, hinges on free-forming structures in their…