Researchers measure nanometer scale temperature

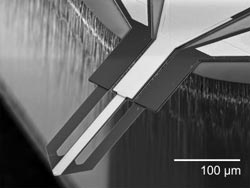

This is an electrothermal cantilever from the University of Illinois, having nanometer-scale electrode tip integrated onto a microheater. Credit: University of Illinois at Urbana-Champaign<br>

Atomic force microscope cantilever tips with integrated heaters are widely used to characterize polymer films in electronics and optical devices, pharmaceuticals, paints, and coatings.

These heated tips are also used in research labs to explore new ideas in nanolithography and data storage, and to study fundamentals of nanometer-scale heat flow. Until now, however, no one has used a heated nano-tip for electronic measurements.

“We have developed a new kind of electro-thermal nanoprobe,” according to William King, a College of Engineering Bliss Professor in the Department of Mechanical Science and Engineering at the University of Illinois at Urbana-Champaign. “Our electro-thermal nanoprobe can independently control voltage and temperature at a nanometer-scale point contact. It can also measure the temperature-dependent voltage at a nanometer-scale point contact.”

“Our goal is to perform electro-thermal measurements at the nanometer scale,” according to Patrick Fletcher, first author of the paper, “Thermoelectric voltage at a nanometer-scale heated tip point contact,” published in the journal Nanotechnology. “Our electro-thermal nanoprobe can be used to measure the nanometer-scale properties of materials such as semiconductors, thermoelectrics, and ferroelectrics.”

The electro-thermal probes are different than thermal nanoprobes typically used in King's group and elsewhere. They have three electrical paths to the cantilever tip. Two of the paths carry heating current, while the third allows the nanometer-scale electrical measurement. The two electrical paths are separated by a diode junction fabricated into the tip. While the cantilever design is complex, the probes can be used in any atomic force microscope.

In addition to Fletcher, co-authors of the paper include Byeonghee Lee, and William King. The research was performed in the Nanoengineering laboratory as well as the Micro and Nanotechnology Laboratory and the Materials Research Laboratory at the University of Illinois.

The paper is available online at doi:10.1088/0957-4484/23/3/035401

The research was sponsored by the Office of Naval Research and the Air Force Office of Scientific Research.

Media Contact

More Information:

http://www.illinois.eduAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…