Ice study could stop people slip-sliding away

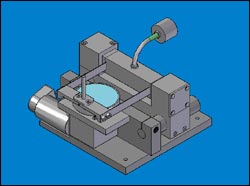

The researchers have developed a Tribometer to perform the friction experiments. They then use the Low Temperature Scanning Electron Microscope to study the ‘wear surfaces’ created.

Going out and about in freezing conditions could become safer thanks to fundamental research at the University of Edinburgh into how we slip on ice.

Using funding from the Engineering and Physical Sciences Research Council (EPSRC) researchers at Edinburgh have built a device, known as a Tribometer, to measure the friction generated as different materials, such as rubber or metal, slip across a sample of ice. The Tribometer is designed to investigate how factors such as temperature, object weight, material composition and velocity affect friction.

The team then examines the ice sample using a state-of-the-art Low Temperature Scanning Electron Microscope (LTSEM). This detail of observation has never been done before and allows the team to investigate what is happening to the ice at scales from several millimetres to as small as nanometres.

Obvious products that could benefit from the research include car tyres and shoes. The project has already attracted the involvement of both Ford and Jaguar. Sports engineers could use the data to design better skis and ice skates, except in this case they would be looking to engineer surfaces that do slip more easily. In addition, the Tribometer could also be used to study the efficiency of ‘gritting’ agents.

Dr Jane Blackford, who heads the team, and was also a consultant to the UK Olympic Curling Team who won a gold medal in the 2002 Winter Olympics in Salt Lake City, says, “Although people have studied ice friction before, there are still many open questions. We are aiming to fill in those gaps and understand why friction varies under different conditions.”

The team has already found that the temperature of the ice plays a large role in how it responds when an object begins to slip.

Dr Blackford says, “I hope the data from this project will provide a bedrock of solid information that manufacturers can use to design more effective, slip-resistant surfaces, tailored to the specific ice conditions in which they will be used.”

Media Contact

More Information:

http://www.epsrc.ac.ukAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…