Hollow optical fibres for UV light

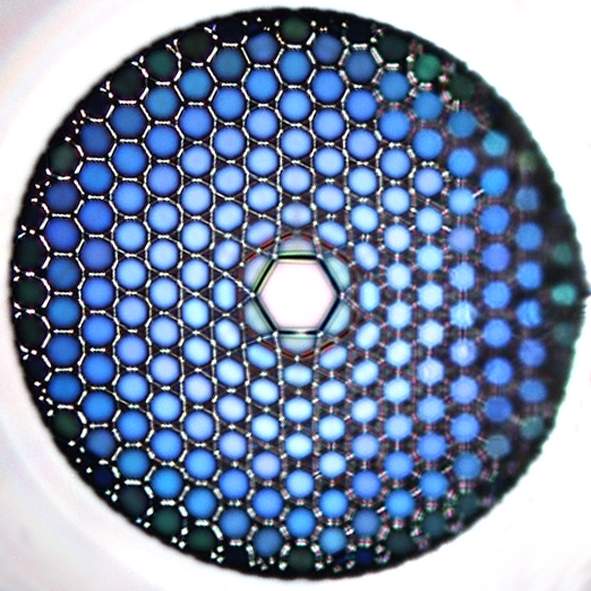

Microscopic image of a hollow-core optical fibre (Photo: MPL)

For certain applications, such as spectroscopic investigations on ions or atoms, however, (laser) light in the ultraviolet range is required. But this type of light would quickly damage conventional optical fibres.

Researchers from the Max Planck Institute for the Science of Light (MPL) in Erlangen/Germany and of the QUEST Institute, based at the Physikalisch-Technische Bundesanstalt (PTB), have tested a new type of optical fibre with a hollow core and have found out that this type of optical fibre was able to guide UV laser light without being damaged and with acceptable loss.

Their investigations, which they have recently published in the journal “Optics Express”, are interesting for numerous applications: besides precision spectroscopy on atoms or ions and their use in optical atomic clocks or quantum computers, fluorescence microscopy in biology, the investigation of process plasmas, combustion studies on soot or the spectroscopy of greenhouse gases would be other possible fields of application.

Optical fibres usually have a solid glass core. This glass core is coated with an optically thinner material. The laws of physics ensure that a light beam is kept inside such a fibre thanks to total reflection and that it can be transported over long distances without significant loss.

Such optical fibres are therefore widely used worldwide to transport light of different spectral ranges – from the infrared up to the visible light range. UV light, however, has a shorter wavelength and is therefore strongly absorbed by the glass used in most types of optical fibres and the fibres are quickly damaged by UV light.

At the Max Planck Institute for the Science of Light (MPL) in Erlangen, experiments with other types of optical fibre have been carried out for a few years. Now, it has turned out that a certain type of optical fibre is particularly well-suited for UV light: a microstructured photonic crystal fibre (PCF) with a so-called “Kagome structure” – a special pattern consisting of triangles and of hexagons in a regular arrangement – and a hollow core of 20 µm in diameter.

This core ensures a single-mode guiding of the light – i.e. with a spatial intensity distribution similar to the shape of a Gaussian bell-shaped curve. The crucial question was to know whether this transport was really single-mode and damage-free, and this is what the metrological experts from the QUEST Institute at PTB had to find out. Their investigations have shown that in the case of the UV beam used, with a wavelength of 280 nm, single-mode transmission was possible and that even after more than 100 hours in operation at a power of 15 mW, no UV-induced damage could be detected.

The optical fibres have even passed a first application test: the researchers at the QUEST Institute have used them successfully for their spectroscopic investigations on trapped ions. Stabilized by the new fibre, the UV laser beam allows an improved interrogation of the ions' internal state. Besides the users of such spectroscopic methods (for example in astronomy, chemistry or fundamental research in physics), this could also be useful for researchers who are developing quantum computers, since in that field, the internal states of a particle are the new digital 0s and 1s.

Dr. Michael H. Frosz, Head of Fibre Fabrication, Max Planck Institute for the Science of Light,

Günther-Scharowsky-Str. 1, 91058 Erlangen/Germany,

Phone: +49 (0)9131 6877-321,

E-mail: michael.frosz@mpl.mpg.de,

Internet: www.pcfibre.com

Prof. Dr. Piet O. Schmidt, QUEST Institute at PTB,

Phone: +49 (0)531 592-4700,

E-mail: Piet.Schmidt@quantummetrology.de,

Internet: www.quantummetrology.de/quest/eqm

F. Gebert, M. H. Frosz, T. Weiss, Y. Wan, A. Ermolov, N. Y. Joly, P. O. Schmidt, and P. St. J. Russell: Damage-free single-mode transmission of deep-UV light in hollow-core PCF. Optics Express 22, 15388 (2014)

Joint press release of the Max Planck Institute for the Science of Light, Erlangen/Germany, (MPL) and the QUEST Institute of the Physikalisch-Technische Bundesanstalt (PTB)

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…