Making better medicines with a handful of chemical building blocks

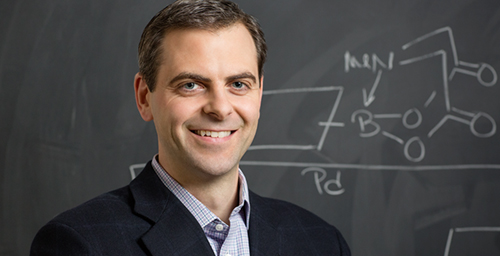

Photo by L. Brian Stauffer University of Illinois chemistry professor Martin Burke led a team that discovered a simple system to synthesize a large class of medically important molecules using only 12 different chemical “building blocks.”

University of Illinois chemist Martin Burke, a pioneer of a technique that constructs complex molecules from simple chemical “building blocks,” led a group that found that thousands of compounds in a class of molecules called polyenes – many of which have great potential as drugs – can be built simply and economically from a scant one dozen different building blocks.

The researchers published their findings in the journal Nature Chemistry.

“We want to understand how these molecules work, and synthesis is a very powerful engine to drive experiments that enable understanding,” said Burke, a chemistry professor at the U. of I. and the Howard Hughes Medical Institute. “We think this is a really powerful road map for getting there.

Once you have the pieces in a bottle, you can make naturally occurring molecules, or you can change the pieces slightly to make them better. Usually, that’s such a herculean task that it slows down research. But if that part becomes on-demand, you can make anything you want, and it can powerfully accelerate the drug discovery process.”

In the same way that plastic building blocks of different sizes and shapes can snap together because they share a simple connector, the chemical building blocks are linked together with one simple reaction. This gives scientists freedom to build molecules that may be difficult or expensive to extract from their natural source or to make in a lab.

One advantage of the building-block approach is that it allows the researchers to mix and match parts to build many different molecules, and to omit or substitute parts to make a potentially therapeutic substance better for human health. For example, Burke’s group recently synthesized a derivative of the anti-fungal medication amphotericin (pronounced AM-foe-TAIR-uh-sin), which led to a big breakthrough in understanding how this clinically vital but highly toxic medicine works and the discovery of another derivative that is nontoxic to human cells while still effective at killing fungus.

After their success in synthesizing derivatives of amphotericin, which fall into the polyene category, the researchers wondered, how many different building blocks would it take to make all the polyenes? (Polyene is pronounced polly-een.)

Looking at the structures of all the known naturally occurring polyenes – thousands in all – Burke and graduate students Eric Woerly and Jahnabi Roy focused on the smaller pieces that made up the molecules and found that many elements were common across numerous compounds.

After careful analysis, they calculated that more than three-quarters of all natural polyene frameworks could be made with only 12 different blocks.

“That is the key most surprising result,” Burke said. “We’ve had this gut instinct that there will be a set number of building blocks from which most natural products can be made. We’re convinced, based on this result, that we can put together a platform that would enable on-demand assembly of complex small molecules. Then researchers can focus on exploring the function of these molecules, rather than spending all their time and energy trying to make them.”

Watch a video of Burke explaining the building block approach.

To demonstrate this surprising finding, the researchers synthesized several compounds representing a wide variety of polyene molecules using only the dozen designated building blocks. Many of these building blocks are available commercially thanks to a partnership between Burke’s group and Sigma-Aldrich, a chemical company.

Burke hopes that identifying the required building blocks and making them widely available will speed understanding of polyene natural products and their potential as pharmaceuticals, particularly compounds that until now have been left unexplored because they were too costly or time-consuming to make.

Burke’s group hopes eventually to identify and manufacture a set of building blocks from which any researcher – trained chemist or not – can build any small molecule.

“Now that we have this quantifiable result, that with only 12 building blocks we can make more than 75 percent of polyenes, we are committed to figuring out a global collection of building blocks – how to make them, how to put them together – to create a generalized approach for small-molecule synthesis.”

The National Institutes of Health supported the work.

The paper, “Synthesis of most polyene natural product motifs using just 12 building blocks and one coupling reaction,” is available online.

Media Contact

More Information:

http://www.illinois.eduAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…