Ancestors skip adolescence

Teeth tell the tale of early hominid lives. <br>© SPL <br>

Dental diary of a teenage hominid aged 1.5 million years.

Our early ancestors never went through the awkward age, suggests a new analysis of dental records. Extended youth may have emerged relatively late in human evolution.

Although apes cut the apron strings at around 12 years, despairing human parents are well aware that their kids take at least 18 years to grow up. The development of this prolonged growth period is seen as a key event in human evolution, allowing extra time for learning.

Homo erectus, our 1.5-million-year-old ancestor, was previously assumed to have developed like us. In fact, it grew up more like an ape, Christopher Dean of University College London and his colleagues have found1. H. erectus was fully grown at 14-16 years, Dean estimates.

The creatures shortened their growth by dodging adolescence, says anthropologist Barry Bogin of the University of Michigan in Dearborn. The terrible teens evolved later to allow us to learn about parenthood, he suggests. Homo sapiens need practice because “we deal with social complexities that Homo erectus didn’t have”.

But Dean argues that the phase in modern human growth missing from Homo erectus’ history cannot be pinned down to adolescence based on current evidence.

Dental history

Dean’s team charted our ancestors’ growth spurts using teeth. Our wisdom teeth emerge at 18, but apes’ erupt at 11. On a finer scale, tiny daily oscillations in the activity of cells that secrete enamel are recorded as microscopic lines in the tooth’s crown. “You can see every day in the life of a human,” Dean explains. Thinner increments show that modern humans have a slower rate of growth.

By totting up periodic ridges on the outside of teeth, the team calculated dental-formation times in fossilized skeletons of the youth of yesteryear: from H. erectus to Neanderthals, who lived 300,000 years ago, to apes. Homo erectus gained their first molars at around 4 to 4.5 years, the team estimate, closer to apes at 3.5 years than to humans at age 6.

The slightly longer childhood matches Homo erectus’ slightly bigger brain, says Jacopo Moggi-Cecchi, who studies human evolution at the University of Florence in Italy. In addition to cultural development, humans’ protracted growth allows extra time for brain development, he argues.

The fact that Homo erectus carried itself like a human led to the assumption that it grew up like one, explains Moggi-Cecchi – yet its brain size and dentition suggest it fits an earlier evolutionary pattern.

References

- Dean, C. et al. Growth processes in teeth distinguish modern humans from Homo erectus and earlier hominins. Nature, 414, 628 – 631, (2001).

Media Contact

More Information:

http://www.nature.com/nsu/011206/011206-10.htmlAll latest news from the category: Interdisciplinary Research

News and developments from the field of interdisciplinary research.

Among other topics, you can find stimulating reports and articles related to microsystems, emotions research, futures research and stratospheric research.

Newest articles

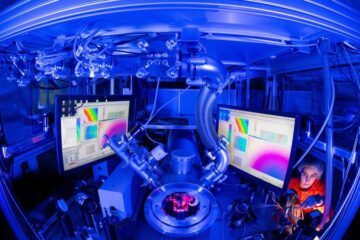

Caution, hot surface!

An international research team from the University of Jena and the Helmholtz Institute Jena are demystifying the mechanisms by which high-intensity laser pulses produce plasma on the surface of solids….

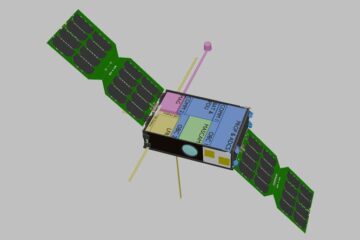

Exploring the Asteroid Apophis With Small Satellites

In five years’ time, a large asteroid will fly very close to Earth – a unique opportunity to study it. Concepts for a national German small satellite mission are being…

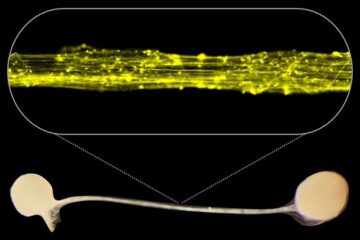

First model of the brain’s information highways developed

Our human brain is not only bigger and contains more neurons than the brains of other species, but it is also connected in a special pattern: Thick bundles of neurons…