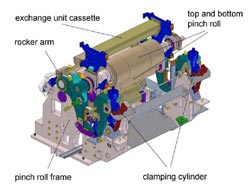

Siemens introduces new quick-exchange pinch-roll cassette for hot-strip mill downcoilers

The new pinch-roll quick-exchange unit from Siemens VAI reduces roll-replacement times from up to eight hours down to just ten minutes<br>

Siemens VAI Metals Technologies now offers hot-strip mill operators a new method for changing the pinch rolls in downcoilers. The pinch-roll unit, designed as a quick-exchange cassette, can be replaced within just ten minutes without additional interruption of production. That saves up to eight hours typically required when applying conventional solutions.

This capability to quickly exchange rolls reduces maintenance time, increases yield, and makes it easier to switch from one steel grade to another. Hot-strip producers can thus respond more quickly to changing market demands. Strip can also be coiled at a consistently high quality for longer periods of time. The rolls can be cleaned and refurbished offline, thereby enhancing both strip quality and personnel safety.

During the coiling of hot strip, deposits forming on the pinch rolls have to be removed at frequent intervals in order to prevent damage to the roll surface, which can impair strip quality. The pinch rolls also have to be refurbished at regular intervals, depending on the steel grade rolled and the length of time that the pinch rolls have been in use. Up until now, pinch rolls were manually cleaned inline during ongoing operations, posing a high safety risk for maintenance personnel. A complete roll change required up to eight hours, and this was usually done during scheduled maintenance shutdown periods.

The new pinch-roll quick-exchange unit from Siemens VAI can be replaced within ten minutes. The change is carried out automatically, and cleaning no longer has to be done during ongoing operations. This eliminates a potentially dangerous task for rolling mill personnel. The short time required to replace rolls now allows an exchange to be synchronized with specific operational requirements, such as a change in the grade of steel to be rolled or the specific strip quality requirements. This facilitates a more flexible response to changing market requirements. All in all, the output of the rolling mill can be increased and the surface quality of the strip improves.

Additionally, very little time is lost as a result of unscheduled interruptions caused by damaged pinch rolls.

The capability to change the pinch rolls quickly also enables the cleaning and refurbishing intervals to be ideally timed to optimize the roll-surface condition and length of service life. An optional surface testing system supports the operator to achieve this.

The new pinch-roll quick-exchange unit from Siemens VAI reduces roll-replacement times from up to eight hours down to just ten minutes

The Siemens Industry Sector (Erlangen, Germany) is the world’s leading supplier of innovative and environmentally friendly products and solutions for industrial customers. With end-to-end automation technology and industrial software, solid vertical-market expertise, and technology-based services, the Sector enhances its customers’ productivity, efficiency, and flexibility. With a global workforce of more than 100,000 employees, the Industry Sector comprises the Divisions Industry Automation, Drive Technologies and Customer Services as well as the Business Unit Metals Technologies. For more information, visit www.siemens.com/industry

The Metals Technologies Business Unit (Linz, Austria), part of the Siemens Industry Sector, is one of the world’s leading suppliers of plant construction and engineering in the iron and steel industry as well as in the flat rolling segment of the aluminum industry. The Business Unit offers a comprehensive product and service portfolio for metallurgical plants and equipment as well as integrated automation and environmental solutions covering the entire lifecycle of plants. For more information, visit www.siemens.com/metals

Media Contact

More Information:

http://www.siemens.com/metalsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…