Online Game for Optimal Factory Management

The “Plantville” game is intended not only for students and job applicants, but also Siemens customers, prospects and employees. The challenge for the players is to improve the productivity, efficiency, and sustainability of a simulated factory. Plantville has been online in an English-language version for about 100 days now and already has approximately 16,000 registered players in more than 140 countries.

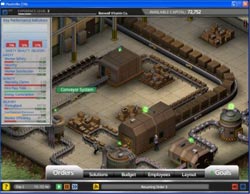

It’s challenging for anyone except perhaps a real-life plant manager to have a clear idea of the tasks faced by a plant engineer. That’s why Siemens Industry selected three typical production facilities for the Plantville computer game: a bottling plant, a vitamin production plant, and a train assembly plant. The objective of the game is to improve the plants’ safety, quality, and deliveries. This calls for the players to optimize energy management, for example, or boost employee satisfaction, while also being able to use Siemens solutions such as energy-saving servo motors, automation systems or sprinkler systems. They also can hire new employees, to raise productivity.

A fourth plant, a “Factory of the Year,” is managed in exemplary fashion by “Pete,” ‑ an avatar ‑ who also gives the players an introduction to the game. Pete, the expert plant manager, gives the participants tips at various points during the game, using short films, puzzles, or online chats in the Plantville Café. The chats feature actual plant experts taking part in discussions at regular intervals that focus on topics including optimization of machines or energy efficiency. And the players can also share their ideas and impressions on Facebook, LinkedIn, and Twitter.

Siemens wants to further develop Plantville. Currently included in the game are Siemens products used in industrial and commercial building applications — from control technology to drive systems to safety systems. The company’s wide-ranging portfolio offers a wealth of other possibilities, though. The game could be expanded to include a university, a hospital, a data center, or a transport system, to name a few examples.

Media Contact

More Information:

http://www.siemens.com/innovationnewsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…