Sensor system improves indoor air quality while making building ventilation more energy efficient

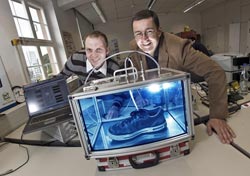

Andreas Schütze (pictured right): His sensor systems find use in a wide range of applications, from detecting chemicals outgassing from individual products to monitoring the quality of indoor air.<br><br>Foto: dasbilderwerk<br>

Energy consumption levels can be halved as a result. Professor Andreas Schütze is an expert in gas sensor technology at Saarland University and is the coordinator of the European research project ‘SENSIndoor’.

Researchers plan to develop a cost-effective, intelligent ventilation system that will automatically supply fresh air to rooms and indoor spaces as and when needed.

The gas sensors detect air contamination due to the presence of volatile organic compounds (VOCs). Using the measurement data and information on when and how rooms are used, the system will be able to adjust the intensity and duration of ventilation. The project is being supported by the EU through a grant worth €3.4 million.

If windows are kept closed, indoor air can become a very unhealthy mix of chemicals, such as formaldehyde from furniture, solvents from carpet adhesives, chemical vapours from cleaning agents, benzene, xylene, and numerous others. This is particularly true when buildings have been well insulated and sealed to reduce energy costs. But what is good in terms of heat loss and energy efficiency, may not be so good for the health of those who live and work there.

Many volatile organic compounds are carcinogens and represent a health hazard particularly to children and older people. ‘If rooms are properly ventilated health hazards can be avoided. Unfortunately, our noses are usually unable to detect the presence of such contaminants, even when they are present at levels hazardous to health,’ explains project coordinator Andreas Schütze. Too much ventilation also results in high levels of heat loss, which has a negative cumulative effect on energy costs and the environment.

‘The sensor system that we are currently developing will maintain high-quality indoor air with the lowest possible contaminant levels while ensuring energy efficiency by means of automatic, customized ventilation,’ explains Professor Schütze. ‘The health hazards associated with high contaminant concentrations can therefore be avoided while at the same time reducing energy consumption in buildings by about fifty percent, which is highly significant in terms of existing carbon emission targets,’ says Schütze.

These highly sensitive artificial sense organs can reliably detect gases of all kinds, from toxic carbon monoxide to carcinogenic organic compounds, and can determine their concentrations quantitatively. Even the smallest quantities of trace gases do not go undetected by the sensors. The novel metal oxide semiconductor (MOS) gas sensors and so-called gas-sensitive field-effect sensors, which Schütze has been developing in collaboration with partners in Sweden, Finland and Switzerland, are able to detect air contaminants such as formaldehyde, benzene or xylene at concentrations well below one in a million.

However, in order to be used for the proposed application, the sensitivity of the monitoring system will need to be improved even further. The sensor system therefore collects molecules in the air over a known period of time and then quantitatively measures the amounts collected – an approach which significantly reduces the system’s detection threshold.

‘If the concentration of a particular molecule is above a specified limit, fresh air is automatically introduced to modify the composition of the air and re-establish good air quality. If all of the rooms in a building are equipped with our sensors and if the sensors are connected to an intelligent ventilation control unit, the system can ventilate each room in a way that has been optimized for the specific use to which that room is put.

For example, if there is a problem with contaminants in the indoor air of a school building, classroom ventilation can be adapted to fit in with teaching periods and break times,’ explains Schütze. The researchers within the SENSIndoor project will therefore be studying and evaluating a variety of ventilation scenarios in schools, office buildings, homes and residential buildings. The objective is to learn more about ventilation patterns and requirements in these buildings so that the system can provide optimized ventilation under any given conditions.

Research institutions and industrial partners from Sweden (Linköping University and Sensic AB), Finland (University of Oulu and Picodeon LTD OY), Switzerland (SGX Sensortech SA), France (SARL Nanosense) and Germany (Saarland University, Fraunhofer Institute for Chemical Technology, 3S GmbH and Eurice GmbH) will be working together within the SENSIndoor project.

The project has received funding totalling €4.6 million over a period of three years, of which €3.4 million has come from the EU as part of the Seventh Framework Programme (FP7). Approximately €1 million will be used to fund project research carried out in Saarland.

Contact: Prof. Dr. Andreas Schütze, Measurement Technology Lab, Saarland University, Saarbrücken, Germany: Tel. +49 (0)681 302-4663, E-mail: schuetze@lmt.uni-saarland.de

Press photographs are available at http://www.uni-saarland.de/pressefotos and can be used at no charge.

Note for radio journalists: Studio-quality telephone interviews can be conducted using broadcast audio IP codec technology (IP direct dial or via the ARD node 106813020001). Contact: Press and Public Relations Office +49 (0)681302-2601, or -64091.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

New insights into the mechanisms of chromosome segregation errors

Research on centromere structure… Researchers from the Kops group in collaboration with researchers from the University of Edinburgh, made a surprising new discovery in the structure of the centromere, a structure…

“Topological hall effect” in two-dimensional quantum magnets

In a recent study published in Nature Physics, researchers from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, together with researchers of University of Science and Technology of China, have introduced the…

Coating Technologies of the Future

LZH and Cutting Edge Coatings at Optatec… At Optatec 2024, the Laser Zentrum Hannover e.V. (LZH) and Cutting Edge Coatings GmbH (CEC) present new opportunities in coating technologies for the…