Georgia Tech Develops Inkjet-Based Circuits at Fraction of Time and Cost

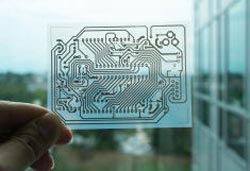

A single-sided wiring pattern for an Arduino micro controller was printed on a transparent sheet of coated PET film.<br>

The technique, called instant inkjet circuits, allows the printing of arbitrary-shaped conductors onto rigid or flexible materials and could advance the prototyping skills of non-technical enthusiasts and novice hackers.

“We believe there is an opportunity to introduce a new approach to the rapid prototyping of fully custom-printed circuits,” said Gregory Abowd, Regents’ Professor in the School of Interactive Computing at Georgia Tech and an investigator in the study. “Unlike existing methods for printing conductive patterns, conductivity in our technique emerges within a few seconds and without the need for special equipment.”

Recent advances in chemically bonding metal particles allowed the researchers to use silver nanoparticle ink to print the circuits and avoid thermal bonding, or sintering, a time-consuming and potentially damaging technique due to the heat. Printing the circuits on resin-coated paper, PET film and glossy photo paper worked best. Researchers also made a list of materials to avoid, such as canvas cloths and magnet sheets.

“Everything we introduced in our research is available in the market and makes it possible for people to try this at home,” said Yoshihiro Kawahara, Associate Professor at the University of Tokyo and the primary investigator who developed the methodology while in Atlanta. “The method can be used to print circuit boards, sensors and antennas with little cost, and it opens up many new opportunities.”

To make the technique possible, researchers optimized commercially available tools and materials including printers, adhesive tape and the silver ink. Designing the circuit itself was accomplished with desktop drawing software, and even a photocopy of a drawing can produce a working circuit.

Once printed, the circuits can be attached to electronic components using conductive double-sided tape or silver epoxy adhesive, allowing full-scale prototyping in mere hours. The homemade circuits might allow tinkerers to quickly prototype crude calculators, thermostat controls, battery chargers or any number of electronic devices.

“Using this technology in the classroom, it would be possible to introduce students to basic electronics principles very cheaply, and they could use a range of electronic components to augment the experience,” said Steve Hodges, a team member from Microsoft Research.

To show the capabilities of the new technique for capacitive touch sensing – the interaction prominent in smartphone interfaces – and the flexibility of the printed circuits, the researchers attached a capacitive ribbon with embedded inkjet-printed circuits into a drinking glass. The capacitive ribbon sensor formed to the contour of the glass and, when connected to a micro controller, was able to measure how much liquid was left in the glass.

The details for replicating the process were presented at the 2013 ACM International Joint Conference on Pervasive and Ubiquitous Computing (UbiComp 2013) in Zurich, Switzerland, Sept. 8-12. The research “Instant Inkjet Circuits: Lab-based Inkjet Printing to Support Rapid Prototyping of UbicComp Devices” won a best paper award at the conference and can be found here: http://dl.acm.org/citation.cfm?id=2493486.

Media Contact

More Information:

http://www.gatech.eduAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…