DuPont sharpens its focus on lightweighting solutions

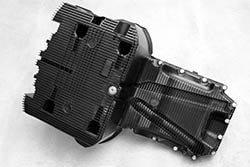

Image: DuPont/ElringKlinger<br> New truck oil pan made of DuPont™ Zytel® polyamide resin, injection moulded by ElringKlinger for Mercedes-Benz, is up to 6 kgs (50 percent) lighter than aluminium, can resist stone and gravel chip impact during the typical 1.5 million kilometre lifetime of a truck or bus engine, and integrates functions not possible with metal.<br>

DuPont shows how advanced materials, design and processing converge to help automakers cut CO2 emissions, conserve fuel

Innovative technology and material solutions to automotive lightweighting — helping automakers take weight out of vehicles to reduce emissions and improve fuel economy — are currently top of DuPont Performance Polymers R&D agenda. The policy embraces collaborative developments with the industry to help get innovation into the market faster. Latest examples include a truck oil pan of DuPont™ Zytel® polyamide resin up to 6 kgs (50 percent) lighter than the aluminium it replaces, and a developmental thermoplastic composite technology that combines metals-replacing lightness, strength and stiffness in structural, load bearing and crash-protection parts for body-in white, suspension or underhood applications.

These technologies will be featured on the DuPont Stand C43, Hall 06, at K 2013, Düsseldorf, Germany, October 16-23, 2013.

Lightweighting has been identified by the auto industry as a critical way to improve fuel efficiency and reduce CO2 emissions. DuPont is collaborating with industry to develop lighter weight components that meet performance requirements by designing first for inherently lightweight plastics.

“Designing for plastic rather than using plastic in a component designed for metals requires a different approach and material data, but helps ensure all the lightweighting, strength and functional benefits are captured,” said Patrick Cazuc, automotive director EMEA, DuPont Performance Polymers. To support this, DuPont is characterizing its materials in more dynamic situations.

“Testing we have done with the industry shows that we are able to better predict performance, helping to improve the material selection process and speed the development time.”

It has been estimated that reducing an automobile’s total weight by just 50kg can reduce CO2 emissions by up to 5g/km, and increase fuel economy by up to 2 percent. In engines alone, replacing metal with plastic in known engine applications can eliminate at least 11 kgs per vehicle, and double the life of parts exposed to high heat in turbo charged engines. Apply that to the 83 million engines scheduled for 2013, and the need for over 1 billion litres of fuel, or almost 10 million barrels of crude oil, can be eliminated.

Plastic solutions

“The auto industry is facing many difficult challenges, the most critical in Europe being CO2 emissions reduction. Coupled with more aggressive engine coolants and temperatures, and the added weight of new performance, comfort and safety features, these challenges are creating major lightweighting opportunities for DuPont’s engineering polymers and high performance elastomers,” Cazuc explained.

“The industry is more open than ever to step changes in design that push the limits of plastics to meet these challenges. Light thermoplastic composites offering enhanced stiffness, and adoption of new oil pans, exhaust mufflers and tailpipes in DuPont plastics, are prime examples. We are collaborating with automakers to get these innovative ideas into the market faster with greater reliability, and at affordable cost.”

Lightweight plastic oil pan

To demonstrate how well this collaboration can work, DuPont will show a large truck oil pan of DuPont™ Zytel® polyamide resin, injection-moulded by ElringKlinger for Mercedes-Benz, that is up to 6 kgs (50 percent) lighter than aluminium, and can resist stone and gravel chip impact during the typical 1.5 million kilometre lifetime of a truck or bus engine. There is also a 2dB reduction in noise level compared with metal.

Reducing component weight translates into better fuel efficiency and sustainability without compromising safety, while helping to meet tough Euro 6 emission limits. The use of lightweight Zytel® polyamide resin also enables the integration of functions not possible with metal.

Lighter, stronger structures

To meet a critical need for lighter, stronger structural materials, DuPont is working with automakers and tier one component manufacturers on developmental projects using thermoplastic composites for structural or load-bearing components, such as seat structures, lift-gates, crossmembers, bumper beams and suspension systems.

Work with PSA Peugeot Citroen on testing a side impact beam using DuPont™ Vizilon®, a developmental thermoplastic composite technology, showed a 40 percent weight reduction compared to ultra-high strength (UHHS) steel, while absorbing more energy than metal and short glass-fibre polymer beams. As a result, DuPont™ Vizilon® passed PSA Peugeot Citroën’s crash test, making it well suited for crash components. Vizilon® also offers stiffness performance in temperatures from -40°C to +90°C, and outperforms polypropylene-based composites above 80°C.

Investments in advanced materials

DuPont is focused on reducing dependence on fossil fuels, with investments in advanced materials and expert application development, especially in lighter weight alternatives to metals that can withstand the intense heat, aggressive chemicals and constant high pressures in modern automotive engines.

The goal is to significantly reduce component weight without compromising structural performance and sustainability, to help automakers reduce total vehicle weight, cut CO2 emissions, and build a secure energy future.

Much of the developmental work is carried out at DuPont’s eleven Innovation Centres worldwide, connecting customers, strategic partners and academics with more than 10 000 DuPont scientists and engineers. Four of these centres are focused on the automotive industry, where the company’s global development teams work on five innovative pathways to lightweighting, engine efficiency, bio-based solutions, electrification and alternative drive systems.

DuPont offers more than 100 materials and product families for the global automotive industry. Through its global application development network, DuPont Automotive is committed to collaborating with customers throughout the value chain to develop new products, materials, components and systems that help reduce dependence on fossil fuels and protect people and the environment. For more information, visit automotive.dupont.com.

DuPont Performance Polymers is committed to working with customers throughout the world to develop new products, components and systems that help reduce dependence on fossil fuels and protect people and the environment. With more than 40 manufacturing, development and research centers throughout the world, DuPont Performance Polymers uses the industry’s broadest portfolio of plastics, elastomers, renewably sourced polymers, filaments and high-performance parts and shapes to deliver cost-effective solutions to customers in aerospace, automotive, consumer, electrical, electronic, industrial, sporting goods and other diversified industries.

DuPont (NYSE: DD) has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. The company believes that by collaborating with customers, governments, NGOs, and thought leaders we can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on fossil fuels, and protecting life and the environment. For additional information about DuPont and its commitment to inclusive innovation, please visit www.dupont.com.

The DuPont Oval Logo, DuPont™, The miracles of science™ and all product names denoted with ® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company or its affiliates.

PP-EU- 2013-04

DuPont press contact

Rémi Daneyrole

Tel.: +41 (0)22 717 54 19

Fax: +41 (0)22 580 22 45

remi.daneyrole@dupont.com

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…