Safe energy transport made easy – Adaptive processing of complex control data

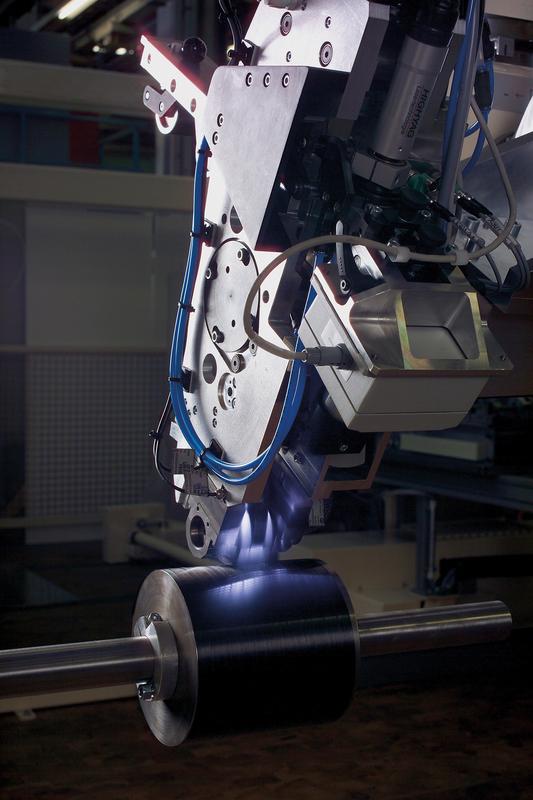

Tape winding process Source: Fraunhofer IPT

Pipes used for oil and gas transport in the deep sea must be able to withstand extreme loads caused by waves and pressure while remaining resistant against corrosion and weathering at all times. Wound pipes made of fiber-reinforced plastics are particularly well suited for riser systems as they can also be used to transport oil and gas in ultra-deepwater areas.

The advantage of the material to the application of metal within these structures: The heavy-duty and very corrosion-resistant fiber-reinforced plastics substitute the metallic strengthening layers in multi-layered riser pipes, which leads to a reduction of their dead load. Considering that these pipes can have a length of two to three kilometers, this is a substantial advantage for the overall performance of the pipe system.

Everything under control: synchronization of laser and winding system

The laser, which is used for melting the matrix material during the winding process, has to release a precisely defined amount of energy into the process zone. Concurrently, the system and the semi-finished product, i.e. the yet unmelted material, are in constant movement throughout the running process.

A large amount of control data has to be calculated and transferred in real-time in order to ensure that the winding process is continuously running. That is the only way to guarantee that the material will not overheat while the individual layers are sufficiently welded to each other.

In order to optimally synchronize all components of the system, the thermal characteristics in the process zone are recorded with a thermal imaging camera. Concurrently, a simulation software and data mining algorithms perform an analysis during the process. This allows for a precise determination of thermal energy that is required for the imminent welding process.

In conjunction with newly developed laser optics and on the basis of the data analysis, the machine control system is able to instantly regulate and adapt both power and intensity distribution of the heat source. At the same time, the continuous monitoring of the winding quality, right behind the process zone, ensures that the production system can progressively approach the optimal processing speed.

Quality monitoring and response in real-time

The online quality monitoring is connected to the control system and directly responds to the user by means of a newly developed man-machine interface, giving feedback on the running process and the condition of the component. Moreover, it allows the user to immediately intervene in the process if needed. That way, the manufacturing processes can be exhausted to their limits without endangering the quality of the final components.

The networking of all system and software components through suitable interfaces and data processing is a prerequisite. Data is consistently structured and imported into databases, then sorted and evaluated by appropriate analytical methods. These include reliability analyses, which can prolong the lifetime of the overall system, as well as lifetime inspections for the manufactured products that also take into account the upstream and downstream stages of the process.

Development work on the individual modules of the new system is nearly complete. Now the modules are to be integrated into a functional tape winding system at the Fraunhofer IPT and connected to the model-based control system. Subsequently, the project partners plan to use the ambliFibre system to manufacture pipes and pressure tanks with a resilience that is compared to conventionally manufactured components.

In the upstream sector, the pipes wound out of fiber-reinforced plastic tapes are then supposed to exploit unconventional oil and gas sources as well. Due to their properties, they are also perfectly suitable for use as transport pipelines. Pressure tanks, which can be manufactured using the winding technique, are of particular interest to the automotive industry and currently have to withstand an internal pressure of up to 15 bar. Provided that the fuel cell technology will gain importance in the future, this technology can furthermore be applied in the manufacturing of hydrogen tanks.

Project partners

– Fraunhofer Institute for Production Technology IPT, Aachen, Germany (coordinator)

– Fraunhofer Institute for Laser Technology ILT, Aachen, Germany

– Pultrex Ltd., Manningtree, United Kingdom

– University of Twente, Enschede, the Netherlands

– MACH4 Lab Srl, Cologno Monzese, Italy

– Video Systems Srl, Codroipo, Italy

– New Infrared Technologies S.L., Madrid, Spain

– Ixun Lasertechnik GmbH, Aachen, Germany

– Life Cycle Engineering Srl, Turin, Italy

– HBN-Teknik A/S, Ringsted, Denmark

– GE Oil & Gas UK Ltd., Newcastle upon Tyne, United Kingdom

– Chair of Optical Systems Technologies (TOS), RWTH Aachen University, Aachen, Germany

– Teaching and Research Field for Design and Development of Microsystems (KEmikro), RWTH Aachen University, Aachen, Germany

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement no. 678875.

Contact

Martin Schäkel M.Sc.

Fraunhofer Institute for Production Technology IPT

Steinbachstrasse 17

52074 Aachen

Germany

Phone +49 241 8904-147

martin.schaekel@ipt.fraunhofer.de

Thias press release and a printable photo are also available on the Internet:

www.ipt.fraunhofer.de/en/Press/Pressreleases/20170516_safe-energy-transport-made-easy-adaptive-processing-of-complex-control-data-in-lightweight-production.html

http://www.ipt.fraunhofer.de/en/Press/Pressreleases/20170516_safe-energy-transpo…

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…