Rutgers Researchers Identify Materials That May Deliver More 'Bounce'

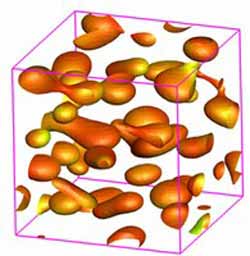

Credit: Physical Review Letters<br>Nano-sized particles embedded in alloys can make alloys highly elastic and enable them to convert electrical and magnetic energy into movement.<br>

Rutgers researchers have identified a class of high-strength metal alloys that show potential to make springs, sensors and switches smaller and more responsive.

The alloys could be used in springier blood vessel stents, sensitive microphones, powerful loudspeakers, and components that boost the performance of medical imaging equipment, security systems and clean-burning gasoline and diesel engines.

While these nanostructured metal alloys are not new – they are used in turbine blades and other parts demanding strength under extreme conditions – the Rutgers researchers are pioneers at investigating these new properties.

“We have been doing theoretical studies on these materials, and our computer modeling suggests they will be super-responsive,” said Armen Khachaturyan, professor of Materials Science and Engineering in the Rutgers School of Engineering. He and postdoctoral researcher Weifeng Rao believe these materials can be a hundred times more responsive than today’s materials in the same applications.

Writing in the March 11 issue of the journal Physical Review Letters, the researchers describe how this class of metals with embedded nanoparticles can be highly elastic, or “springy,” and can convert electrical and magnetic energy into movement or vice-versa. Materials that exhibit these properties are known among scientists and engineers as “functional” materials.

One class of functional materials generates an electrical voltage when the material is bent or compressed. Conversely, when the material is exposed to an electric field, it will deform. Known as piezoelectric materials, they are used in ultrasound instruments; audio components such as microphones, speakers and even venerable record players; autofocus motors in some camera lenses; spray nozzles in inkjet printer cartridges; and several types of electronic components.

High Resolution VersionIn another class of functional materials, changes in magnetic fields deform the material and vice-versa. These magnetorestrictive materials have been used in naval sonar systems, pumps, precision optical equipment, medical and industrial ultrasonic devices, and vibration and noise control systems.

The materials that Khachaturyan and Rao are investigating are technically known as “decomposed two-phase nanostructured alloys.” They form by cooling metals that were exposed to high temperatures at which the nanosized particles of one crystal structure, or phase, are embedded into another type of phase. The resulting structure makes it possible to deform the metal under an applied stress while allowing the metal to snap back into place when the stress is removed.

These nanostructured alloys might be more effective than traditional metals in applications such blood vessel stents, which have to be flexible but can’t lose their “springiness.” In the piezoelectric and magnetorestrictive components, the alloy’s potential to snap back into shape after deforming – a property known as non-hysteresis – could improve energy efficiency over traditional materials that require energy input to restore their original shapes.

In addition to potentially showing responses far greater than traditional materials, the new materials may be tunable; that is, they may exhibit smaller or larger shape changes and output force based on varying mechanical, electrical or magnetic input and the material processing.

The researchers hope to test the results of their computer simulations on actual metals in the near future.

The Rutgers team collaborated with Manfred Wittig, professor of Materials Science and Engineering at the University of Maryland. Their research was funded by the National Science Foundation and the U.S. Department of Energy.

Media Contact: Carl Blesch

732-932-7084 x616

E-mail: cblesch@ur.rutgers.edu

Media Contact

More Information:

http://www.rutgers.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…