Researchers from Saarbruecken arrange nanoparticles like "giant atoms"

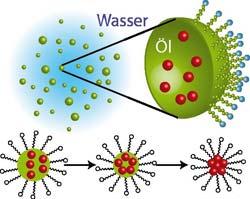

As th oil droplets (green) evaporate, nanoparticles (red) assemble in an orderly manner<br><br>Foto: INM

Through their findings, the researchers are now able to make precisely defined structures from nanoparticles. Normally, nanoparticles form rather disordered, often loose and fuzzy clusters. The results were recently published in the scientific magazine “Nano Letters”.

The researchers assume that this unexpected behavior derives from the smallness of the nanoparticles. “We assume that the nanoparticles with a core diameter of only six nanometers show a behavior similar to atoms: They move very fast, collide with each other and attract each other”, explains Tobias Kraus, head of the Structure Formation Group. Therefore, they can assemble almost as orderly as atoms.

Depending on the number of nanoparticles, the scientists can now predict which three-dimensional lattice are formed by the particles. “Imagine that clusters with 20 particles look like a sphere, whereas 40 particles arrange rather like a cube and 60 particles form a pyramid”, explains Kraus, who holds degrees in materials science and chemical engineering. It is possible to produce specific shapes by defining the quantity of the nanoparticles in the production process. “Since nanoparticles arranged as a sphere have different properties than nanoparticles arranged as a cube, we can influence properties by the number of the particles”, says Kraus. “A rather elongated cluster may not fit through the pores of a filter, for example, although it contains more particles than a spherical cluster.”

The scientists use a well-established principle to force the nanoparticles into this highly ordered structure. To begin with, all gold nanoparticles must be of the same size, which is achieved in a classic preparation procedure: The researchers dissolve little bars of gold in a concentrated acid, combine the dissolved gold with organic molecules and add surface-active substances. When heating this mixture, the scientists obtain nanoparticles with a diameter of six millionths of a millimeter. The nanoparticles swim in oil, which is then dispersed into droplets. Each droplet contains several nanoparticles. “As these droplets evaporate, the space for the nanoparticles is increasingly reduced so that they assemble in an orderly manner and form the ordered clusters”, says Kraus.

In the future, the group will integrate various particles into the clusters, each of them having a different task. This may be a first step to building microscopic machinery from particles.

Original publication: Johann Lacava, Philip Born, Tobias, Kraus, “Nanoparticle Clusters with Lennard-Jones Geometries”, Nano Letters, DOI: 10.1021/nl3013659

Contact:

Dr. Tobias Kraus

Structure Formation Group

INM – Leibniz Institute for New Materials

Phone: +49 681 9300 389

Email: tobias.kraus@inm-gmbh.de

INM is focused on the research and development of materials – for today, tomorrow and the future. Chemists, physicists, biologists, materials and engineering scientists shape the work at INM. From molecule to pilot production, they follow the recurring questions: Which material properties are new, how can they be investigated and how can they be used in the future?

INM – Leibniz Institute for New Materials, situated in Saarbruecken/Germany, is an internationally leading centre for materials research. It is a scientific partner to national and international institutes and a provider of research and development for companies throughout the world. INM is an institute of the Scientific Association Gottfried Wilhelm Leibniz and employs around 180 collaborators. Its main research fields are Chemical Nanotechnology, Interface Materials, and Materials in Biology.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…