Researchers Devise New Means For Creating Elastic Conductors

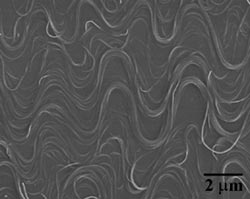

The buckled nanotubes look like squiggly lines on a flat surface.<br>

“We’re optimistic that this new approach could lead to large-scale production of stretchable conductors, which would then expedite research and development of elastic electronic devices,” says Dr. Yong Zhu, an assistant professor of mechanical and aerospace engineering at NC State, and lead author of a paper describing the new technique.

The buckled nanotubes look like squiggly lines on a flat surface.

Stretchable electronic devices would be both more resilient and able to conform to various shapes. Potential applications include devices that can be incorporated into clothing, implantable medical devices, and sensors that can be stretched over unmanned aerial vehicles.

To develop these stretchable electronics, one needs to create conductors that are elastic and will reliably transmit electric signals regardless of whether they are being stretched.

One way of making conductive materials more elastic is to “buckle” them. Zhu’s new method buckles carbon nanotubes on the plane of the substrate. Think of the nanotubes as forming squiggly lines on a piece of paper, rather than an accordion shape that zigs up and down with only the bottom parts touching the sheet of paper. Zhu’s team used carbon nanotubes because they are sturdy, stable, excellent conductors and can be aligned into ribbons.

The new process begins by placing aligned carbon nanotubes on an elastic substrate using a transfer printing process. The substrate is then stretched, which separates the nanotubes while maintaining their parallel alignment.

Strikingly, when the substrate is relaxed, the nanotubes do not return to their original positions. Instead, the nanotubes buckle – creating what looks like a collection of parallel squiggly lines on a flat surface.

The carbon nanotubes are now elastic – they can be stretched – but they have retained their electrical properties.

The key benefit of this new method is that it will make manufacturing of elastic conductors significantly more efficient, because the carbon nanotubes can be applied before the substrate is stretched. This is compatible with existing manufacturing processes. “For example, roll-to-roll printing techniques could be adapted to take advantage of our new method,” Zhu says.

A paper describing the new approach, “Buckling of Aligned Carbon Nanotubes as Stretchable Conductors: A New Manufacturing Strategy,” was published online Jan. 23 in Advanced Materials. The paper was co-authored by Feng Xu, a Ph.D. student at NC State. The research was funded by the National Science Foundation.

In another new paper, Zhu’s team has demonstrated for the first time that carbon nanotubes can be buckled using a technique in which the elastic substrate is stretched before the nanotubes are applied. The substrate is then relaxed, forcing the nanotubes to buckle out of plane. The nanotubes form a ribbon that curves up and down like the bellows of an accordion. This second technique has been used before with other materials. This second paper, “Wavy Ribbons of Carbon Nanotubes for Stretchable Conductors,” was published Jan. 19 in Advanced Functional Materials.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…