Why anyone can make a sandcastle

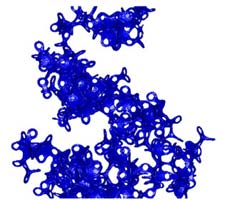

X-ray microtomography of a dense fluid cluster consisting of spherical glass beads (0.8 millimetres in diameter). Image: Max Planck Institute for Dynamics and Self-Organisation

Anyone trying to build sandcastles on the beach will need some degree of skill and imagination, but not an instruction manual. The water content is actually relatively unimportant to the mechanical properties of the sand.

This observation, which is borne out by precise measurements in the laboratory, puzzles researchers. Even with water content of just 3%, the fluid inside represents a highly-complex structure. The mechanical stiffness of the wet sand remains practically constant with moisture ranging from less than 1% to well over 10%, although the fluid structure changes enormously internally.

Researchers at the Max Planck Institute for Dynamics and Self-Organisation in Göttingen, the Australia National University in Canberra, the University of Erlangen, and the ESRF in Grenoble have studied the fluid structures in moist granules using x-ray microtomography to discover their laws (Nature Materials, online publication of February 10, 2008).

In medicine, x-ray microtomography is also known as computer tomography. Scientists x-ray an object from various angles to produce an outline image similar to a standard x-ray. A computer evaluates all of these images and determines which kind of three-dimensional structure the object must have to produce the outline images. When scientists use a bright x-ray source, such as the synchrotron source of radiation at the ESRF in Grenoble, computer tomography is produced with a resolution of thousandths of a millimetre. That is sufficient to resolve the tiny, highly-complex fluid structures that form in a moist granule, like inside a sandcastle for example.

What the research team saw was initially quite astonishing. The fluid did not fully push through the granulate structure and therefore did not force the air out of the interstitial space. More significantly, a filigree structure emerged in which the fluid, grains and air existed equally side by side. The reason for this is easy to understand. As the fluid moistens the grains (it would not otherwise be possible to get them into the granule), it tries to surround itself with as much “grain” as possible. This is best achieved at the points of contact where two grains touch. The “empty” space in between is relatively unattractive for the fluid and fills with air.

When the Göttingen scientists then carried out a more exact study of the geometry of these filigree fluid structures, they established that not only did they all have the same pressure, but that the pressure had to be independent of the fluid content. This explains the universal stiffness of the material. The equal pressure corresponds to an equal force inside and therefore results in the moist granules having the same mechanical properties. “These properties are not only significant to the building of sandcastles,” said Stephan Herminghaus, the head of the study. “They are relevant to the pharmaceutical and food-production industries and help us to understand certain natural catastrophes, such as landslides. Wet granules are relevant in many fields and we now have a better understanding of their mechanical properties.”

Original work:

M. Scheel, R. Seemann, M. Brinkmann, M. DiMichiel, A. Sheppard, B. Breidenbach, S. Herminghaus

Morphological clues to wet granular pile stability

Nature Materials, March edition 2008 Online publication at http://www.nature.com/nmat/index.html

Media Contact

More Information:

http://www.mpg.de/english/All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…