Noise reduction leads to more comfort

The new acoustic test shows how much noise the human ear registers despite sound-absorbing textiles. ©Fotolia<br>

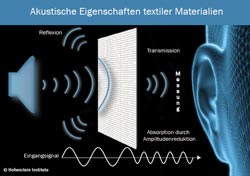

The extent to which a textile material has a sound-absorbing effect and which are the noises that cause wind flow, can now be investigated using acoustic test apparatus at the Hohenstein Institute in Bönnigheim.

Hohenstein scientists in the team working with Dr. Jan Beringer, in conjunction with Hochschule Reutlingen and Rökona Textilwerk GmbH in Tübingen, have developed innovative test methods to investigate the acoustic and aeroacoustic properties of textile materials.

Noise now pervades all parts of our everyday lives and is becoming an increasing source of stress. In addition to the negative effects on the nervous system, studies have shown that it diminishes concentration ability by about 20-30 percent, reduces work performance, increases accident risks and above all decreases feelings of comfort. Even sounds above 40 decibels corresponding approximately to soft radio music can produce these negative effects.

Therefore sound-absorbing textile materials are gaining popularity in the many sectors where sounds are perceived as unpleasant and disruptive. It is primarily in the interior design and automotive sectors where specifically adapted materials are used to minimise and optimise noises leading to a rise in acoustic comfort.

For instance, sound-absorbing ceilings, partitions, floors and furniture surfaces in public facilities, open-plan offices and exhibition halls as well as technical textiles in vehicle interior linings are all effective measures to counter acoustic disturbances.

During the testing process at the Hohenstein Institute different textile materials are investigated with the acoustic measuring device. The fabric to be tested is clamped in a sample holder between a loud speaker and a measuring microphone. One great benefit here is the small sample size as fabric samples measuring only 10 x 10 cm are large enough. Measurements are taken within a frequency spectrum of 200 – 20,000 Hz to ascertain the extent (decibels) to which the fabric attenuates/dampens the signal sent by the loudspeaker.

The aeroacoustic test determines the frequency spectra of the often disturbing background noise of textile air flow. The Hohenstein Institute test apparatus is able to investigate virtually all samples ranging from small laboratory samples up to complete components and can simulate wind speeds of up to 140 km/h.

The textile or component is exposed to air flow and a special measurement microphone is then used to record the noise caused by the air flow. This noise is then subject to computer analysis and the corresponding frequencies of the noise are determined. These resulting comparative figures then enable materials to be optimised for the most diverse of uses.

As well as capturing the aeroacoustic properties of textile fabrics, locally-triggered causes of air flow noises can also be determined. This knowledge can then be used to optimise textile s and components even more.

Contacts:

Hohenstein Institute

Dr. Jan Beringer

j.beringer@hohenstein.de

Media Contact

More Information:

http://www.hohenstein.de/en/inline/pressrelease_12362.xhtmlAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…