Nanoparticles: Polymer knots with silicon hearts

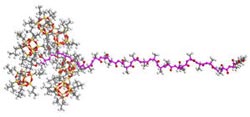

Polylactic acid (PLA)-based organic–inorganic polymers (above) self-assemble into nanoparticle spheres with the potential for drug delivery. During polymerization, PLA (magenta) forms one of two mirror-image structures.<br><br>Reproduced, with permission, from Ref. 1 © 2012 Royal Society of Chemistry<br>

Protein-based drugs show promising activity against many hard-to-treat targets. Getting these biomolecules past the body’s numerous defenses, however, requires innovative technology such as drug-delivering nanoparticles. Polylactic acid (PLA) is a potential candidate because it is non-toxic, biodegradable, and spontaneously assembles into tiny structures under the right conditions.

Chaobin He from the A*STAR Institute of Materials Research and Engineering in Singapore and co-workers have developed a robust method to synthesize PLA nanoparticles using copolymer technology and a rigid ‘nanocage’ made from silicon.

During polymerization, PLA forms into one of two mirror-image compounds, known as L-type or D-type (see image). When chemists mix L- and D-type PLA chains together, their complementary shapes interlock through a process known as stereocomplexation. Recently, chemists have found that constructing PLA chains containing discrete ‘blocks’ of L- and D-compounds brings unprecedented control over nanoparticle formation — allowing them to produce distinct shapes.

Although stereocomplexation improves the mechanical attributes of PLA nanoparticles, many of these compounds aggregate undesirably after a few days in water. He and his team investigated whether they could retain the nanoparticles’ shape using silsequioxane, a stiff and small framework of silicon–oxygen atoms that has a strong record of boosting polymer strength at the molecular level.

After connecting silsequioxane to individual L- and D-type PLA chains, the researchers used a process called atom transfer radical polymerization to generate organic–inorganic hybrid co-polymers with well-defined PLA and silsequioxane segments. When they mixed two block co-polymers with complementary L- and D- PLA segments into polar organic solvents that hold slight electrical charges, the chains self-assembled into nanoscale spheres. Because co-polymers without matching L- and D-segments remained in solution under the same conditions, the team deduced that stereocomplexation is the primary force driving nanoparticle formation.

Experiments revealed that the silicon nanocages significantly improved PLA nanoparticle stability: even after a month in diluted aqueous solution, these hybrid compounds retained their unique shapes. Furthermore, the team found that incorporating longer silsequioxane units into the PLA chains caused the nanoparticles to assemble into smaller spheres. According to He, this suggests that the inorganic constituent can influence the probability of stereocomplexation — findings that open opportunities to precisely tune nanoparticle size and shape.

He and co-workers anticipate that their nanoparticles might enhance the properties of PLA plastics used for medical implants by acting as novel ‘filler’ substances. He explains that the tiny compounds should enhance interfacial adhesion inside large sheets of PLA, thereby augmenting its ductility and toughness.

The A*STAR-affiliated researchers contributing to this research are from the Institute of Materials Research and Engineering

Journal information

Tan, B. H., Hussain, H., Leong, Y. W., Lin, T. T., Tjiu, W. W. & He, C. Tuning self-assembly of hybrid PLA-P(MA-POSS) block copolymers in solution via stereocomplexation. Polymer Chemistry 4, 1250–1259 (2013).

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Red light therapy for repairing spinal cord injury passes milestone

Patients with spinal cord injury (SCI) could benefit from a future treatment to repair nerve connections using red and near-infrared light. The method, invented by scientists at the University of…

Insect research is revolutionized by technology

New technologies can revolutionise insect research and environmental monitoring. By using DNA, images, sounds and flight patterns analysed by AI, it’s possible to gain new insights into the world of…

X-ray satellite XMM-newton sees ‘space clover’ in a new light

Astronomers have discovered enormous circular radio features of unknown origin around some galaxies. Now, new observations of one dubbed the Cloverleaf suggest it was created by clashing groups of galaxies….