Laying the groundwork for a manufacturing revolution

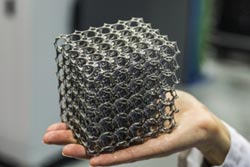

Unlike traditional subtractive fabrication techniques, additive manufacturing can rapidly produce components with complex internal geometries.<br><br>© Latsalomao/iStock/Thinkstock<br>

For centuries, manufacturers have relied on ‘subtractive’ techniques to fabricate objects — cutting, milling and grinding away substances such as ceramic and steel. But the waste associated with traditional processing is becoming problematic as the cost of raw materials increases.

In aerospace applications, for example, up to 90 per cent of high-tech alloys are machined away during component fabrication. Furthermore, devices containing intricate internal features or extremely thin dimensions are difficult to produce with conventional techniques.

New methods of ‘additive’ manufacturing are emerging, however, that could potentially solve these problems and trigger radical changes in traditional economies of scale. Based on three-dimensional (3D) printing technology — which generates 3D objects from computational data by building them up in layers from materials such as plastic or metal — the approach allows rapid production of complex, customized and previously inaccessible designs. Moreover, the precise addition of material minimizes waste for a reduced environmental footprint.

To help prepare manufacturers for the coming revolution in on-demand fabrication, A*STAR has launched a US$12 million Industrial Additive Manufacturing Programme, led by the A*STAR Singapore Institute of Manufacturing Technology (SIMTech). In partnership with Nanyang Technological University (NTU), a leader in additive manufacturing research, the program will advance specific technologies and training to assist Singapore’s diverse range of aerospace, automotive, marine and petroleum manufacturers in the adoption of additive manufacturing techniques — a critical step toward strengthening a sector that contributed over 20 per cent of the country’s gross domestic product in 2012.

“This program aims to develop innovative additive manufacturing technologies and capabilities to transform the manufacturing landscape of Singapore,” says Tan Geok Leng, executive director of A*STAR’s Science and Engineering Research Council. “Singapore is well positioned to respond to the needs of this new growth area and introducing such advanced manufacturing techniques could rejuvenate the existing workforce. Established sectors — such as the precision engineering and aerospace maintenance, repair and overhaul industries — are poised to be the lead demand drivers.”

Answering the billion-dollar question

Forecasts estimate that the market potential of additive manufacturing will expand from its current value of US$2.2 billion to US$10.8 billion in 2021. Although the business outlook is positive, there are many challenges to overcome to achieve this goal. These include the development of appropriate printing materials, machinery design and calibration and post-processing methodologies, in addition to providing workers with the necessary training.

Fortunately, A*STAR is home to a wide spectrum of knowledge and expertise, making it the ideal setting in which to explore new manufacturing technologies. Accordingly, SIMTech and NTU are set to collaborate with two other A*STAR research institutes — the A*STAR Institute of Materials Research and Engineering and the A*STAR Institute of High Performance Computing — by tapping into their expertise in the modeling, simulation and production of novel materials and innovative devices. The four institutes will train students in 3D printing techniques and hope to apply their research findings to Singapore’s manufacturing industry within the next three years.

Six to watch

As part of its remit, the A*STAR–NTU Industrial Additive Manufacturing Programme has identified six key additive manufacturing technologies that could benefit from sustained research.

The first of these, ‘stereolithography’, operates much like an inkjet printer, except that the ‘ink’ is a liquid photopolymer that solidifies under ultraviolet laser light and joins successive layers together to form a 3D object. While this system allows for the speedy production of functional parts and prototypes, it is also prohibitively expensive due to the high cost of proprietary photopolymers. Hence, researchers are seeking out inexpensive photopolymers with improved abilities to withstand sudden impacts. Eventually, they hope to print large-format and lightweight polymer components with customizable internal structures that provide distinct advantages over current designs.

‘Polyjet’ printing is another polymer-based additive manufacturing technique gaining favor. These 3D printers have two different jetting heads — one that sprays an ultraviolet-curable photopolymer and another that emits a gel-like support structure, which can be easily washed away after printing is complete. The A*STAR and NTU research teams intend to use polyjet technology to produce novel geometries, such as honeycomb hexagonal cells, which are sought-after for their strength and light weight but are typically constructed through lengthy and repetitive bonding processes.

The ability of lasers to achieve extreme heating and cooling rates within the near-surface regions of materials while leaving the bulk untouched makes them ideal for use in layer-by-layer assembly techniques. One such technology, ‘laser-aided additive manufacturing’ (LAAM), fabricates metal parts by controlled heating of metal powders — particularly useful for assembling high-value parts from difficult-to-machine metals, such as titanium or nickel alloys. Yet at present, LAAM is simply used in repairs and re-manufacturing. A*STAR and NTU researchers therefore plan to deploy LAAM in the fabrication of innovative, large-format structures, 2 to 8 meters long, which can be used as downhole components in the oil and gas industries or as mold and die inserts for heavy vehicle production.

Another way that powdered materials can be fused together is through the ‘selective laser melting’ (SLM) and ‘selective laser sintering’ (SLS) additive manufacturing techniques. A*STAR researchers are using computational studies to develop material distribution algorithms that will reduce the need for support structures in SLM and physics-based models that address consistency issues in SLS — huge advances for both methods.

The final area of focus for the A*STAR additive manufacturing program will be ‘electron-beam melting’ (EBM), which uses focused beams of electrons instead of photons of light to produce 3D metal parts from powders under high-temperature, low-pressure conditions. EBM is one of the most efficient additive manufacturing processes, producing extremely strong and distortion-free parts. However, dimensional accuracy is difficult to achieve and components often have rough surface finishes — problems that researchers intend to tackle through multidisciplinary investigations.

Maintaining Singapore manufacturing’s competitive edge

With the worldwide 3D printing market now on the verge of taking off, NTU’s dean of engineering, Ng Wun Jern, notes that the Industrial Additive Manufacturing Programme will benefit companies in Singapore by providing support for scaling up and integrating the technology at a critical time in its development.

“Understanding industry needs and developing innovative solutions is key to keeping Singapore’s competitive edge in today’s high-tech manufacturing sector,” says Ng. “NTU and A*STAR are well placed to make this new program a success. Together, we are poised to support our industry’s move into next-generation manufacturing.”

About the Singapore Institute of Manufacturing Technology

The A*STAR Singapore Institute of Manufacturing Technology (SIMTech) develops high-value manufacturing technology and human capital to contribute to the competitiveness of Singapore’s industry. It collaborates with multinational and local companies in the precision engineering, electronics, semiconductor, medical technology, aerospace, automotive, marine, logistics and other sectors.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…