Almost frictionless

Passengers check in their suitcases, which are automatically transported away by conveyer belts; moving walkways and escalators run for hours without a break – thousands of gear units rattle away at the major airports. The power consumption is tremendous, in the range of several gigawatt hours per annum.

A substantial amount of this is lost through friction. In wind turbines and in cars, too, a percentage of the energy is spent on friction – reducing the efficiency factor accordingly. Novel lubricants that almost eliminate the effect of friction could be the answer. Once they have been set in motion, the bearings run and run and run.

But what makes the new lubricant different from the oils that were used to lubricate bearings until now? “This lubricant is made from liquid crystals like the ones we know from flat-screen monitors,” explains Dr. Andreas Kailer, head of department at the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg. “In contrast to normal liquids, the molecules in liquid crystals have a certain orientation – you might compare them to matches with their heads all pointing in the same direction.”

In a joint project with the Fraunhofer Institute for Applied Polymer Research IAP in Potsdam and the Mainz-based company Nematel, the IWM researchers are investigating which liquid crystals are most suitable for use as lubricants, and under what conditions. Their testing unit exerts a certain amount of force on a clamped metal cylinder that is moved back and forth over a supporting contact surface. With which lubricant does the machine require the smallest amount of energy to move the metal cylinder?

While the friction hardly changes when using conventional oil, it drops to almost zero after a while when liquid crystals are used. The time that this takes depends primarily on the pressure with which the moving cylinder is pressed against the contact surface. If you were to compare it to a toboggan, it would correspond to the weight of the child sitting on it. “Liquid crystals have not been suitable as a lubricant for ball bearings until now, as the contact pressure is too high – the friction does not drop far enough.

“For slide bearings, on the other hand, liquid crystals are the perfect solution,” says Kailer. Since liquid crystals have been produced mainly for monitors up to now, they have to be ultra-pure – which makes them very expensive. So the researchers now plan to simplify the synthesis process, since less pure substances are also suitable as lubricants,. “We hope to be able to market a liquid crystal lubricant in three to five years’ time,” says Kailer.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

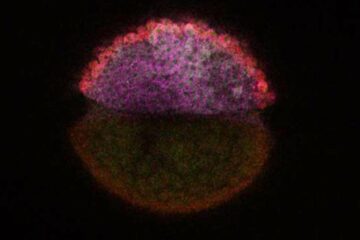

Decoding development: mRNA’s role in embryo formation

A new study at Hebrew University reveals insights into mRNA regulation during embryonic development. The study combines single-cell RNA-Seq and metabolic labeling in zebrafish embryos, distinguishing between newly-transcribed and pre-existing…

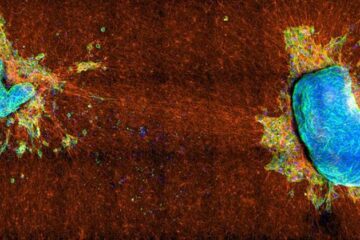

Study sheds light on cancer cell ‘tug-of-war’

How cancer cells tug against each other determines whether they can migrate elsewhere in the body. Understanding how cancerous cells spread from a primary tumor is important for any number…

Latest generation of self-dissolving stents

Magnesium implants support coronary arteries and keep them open. Constricted coronary arteries harbor dangers: Because the heart is not supplied with blood properly, this can lead to pain, cardiac arrhythmia,…