Cement design should take into account the water confined in the smallest pores

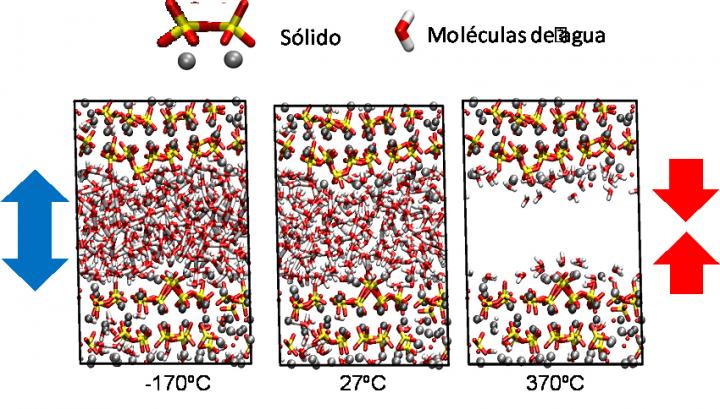

At low temperatures, from inside towards the outside, exerted by the water molecules, and at high temperatures from outside towards the inside caused by the absence of the molecules. Credit: Hegoi Manzano - UPV/EHU

As it is a basic building material used across the world, cement is subjected to a vast range of conditions, both physiological and meteorological, no matter whether they are caused by extreme temperatures and humidity, pressure, etc. It is possible to find conditions ranging from -80 ºC, in places such as the scientific bases in the Antarctic, to several hundreds of degrees in infrastructures close to heat sources or in the case of fires, for example.

These variations in humidity and temperature are translated into physical processes involving evaporation or freezing of the water contained in the cement paste, which often cause stresses and even micro-cracking inside the cement.

Characterizing the response to these phenomena affecting the confined water in the smallest pores of the cement “is hugely important as a large proportion of the water, about 30 %, is located in these small spaces, so to a great extent it contributes towards the final properties of the material,” explained Hegoi Manzano, a researcher in the UPV/EHU's department of Condensed Matter Physics, and author of the study in collaboration with a research group of the University of Tohoku in Japan.

Given the complexity involved in studying the behaviour of the water located in such tiny pores of approximately 1 nanometre in size by means of experimental channels, the researchers resorted to molecular simulation methods that “imitate” the interactions among the atoms that make up the cement in order to determine how they behave as a whole and the properties that these interactions are translated into,” he explained. The temperature range they studied was from -170 ºC to 300 ºC.

Stresses at both extremes

In the results obtained in the simulations they were able to observe that at both extremes of temperature “significant volume changes owing to water physics take place. Through totally opposite effects we arrived at the same consequences”, he remarked. At high temperatures the water evaporates and disappears from the pores. In these conditions the pressure brought to bear by the material itself may cause the empty pores to collapse and micro cracking to be created which, in particularly serious cases, could cause the material to collapse.

At the other extreme, at extremely low temperatures, what happens is that the water freezes and therefore expands. “In these conditions it should be highlighted that the frozen water does not manage to form ice because of the small space in which it is located; the water molecules cannot order themselves to form a crystalline ice structure,” he stressed. But the expansion it undergoes is enough to create stresses in the cement and likewise cause micro cracking.

The information extracted from this study can be used to “modify the formulation of the cement for infrastructures that are going to be located in environments with extreme temperatures. Let us take for example an oil company: knowing the stresses and forces that may be created in the cement, they would have the chance to change certain design factors, such as the additives added to the cement to compensate for the expansion or collapsing of the material in oil wells. That would be the ideal application of the work,” concluded Manzano.

###

Additional information

Hegoi Manzano-Moro has a PhD in Chemistry and works as a Temporary Contractual Lecturer in the UPV/EHU's department of Condensed Matter Physics. This work is the result of the collaboration he has with Patrick A. Bonnaud, a researcher at the University of Tohoku in Japan.

Bibliographical reference

P. A. Bonnaud, H. Manzano, R. Miura, A. Suzuki, N. Miyamoto, N. Hatakeyama, A. Miyamoto. Temperature Dependence of Nanoconfined Water Properties: Application to Cementitious Materials. J. Phys. Chem. C, 2016, 120 (21), pp 11465-11480. DOI: 10.1021/acs.jpcc.6b00944. Publication Date (Web): May 10, 2016

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Making diamonds at ambient pressure

Scientists develop novel liquid metal alloy system to synthesize diamond under moderate conditions. Did you know that 99% of synthetic diamonds are currently produced using high-pressure and high-temperature (HPHT) methods?[2]…

Eruption of mega-magnetic star lights up nearby galaxy

Thanks to ESA satellites, an international team including UNIGE researchers has detected a giant eruption coming from a magnetar, an extremely magnetic neutron star. While ESA’s satellite INTEGRAL was observing…

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…