An abundant and inexpensive water-splitting photocatalyst with low toxicity

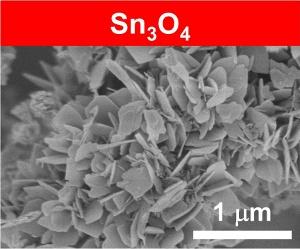

Figure 1 from the press release material. Electron microscope imagery of Sn3O4 catalyst. The synthesized material is a collection of microsized (one millionth of a meter) flaky crystals. Copyright : National Institute for Materials Science (NIMS)

Technology that allows the direct conversion of sunlight, an ultimate renewable energy, into chemical energies (i.e., fuels) that can be condensed and transported is not yet available. As such, solar energy is not ready at present to be utilized in place of conventional fossil and nuclear fuels.

Many water-splitting photocatalysts, such as titanium dioxide (TiO2), can decompose water and produce hydrogen fuel when absorbing ultraviolet light. However, due to their inability to absorb visible light, which accounts for more than half of solar energy, their practical use in the conversion of solar energy is limited.

While the development of new photocatalysts that can split water by absorbing visible light has been worked on globally, there are cost- and environment-related issues because many of the available photocatalysts contain expensive rare metals, such as tantalum, or high concentrations of lead, which is very toxic.

Led by Hideki Abe and Naoto Umezawa, researchers at Japan's National Institute for Materials Science (NIMS) recently discovered a novel photocatalyst by integrating both theoretical and experimental sciences.

The NIMS team searched for oxides containing divalent tin ions (Sn2+) based on the theoretical prediction that such substances may have an electronic structure conducive to water-splitting photocatalytic reactions under the presence of visible light.

As a result, they found a tin oxide, Sn3O4 (Sn2+2Sn4+O4), that is made up of divalent tin ions (Sn2+) and tetravalent tin ions (Sn4+). Their experiment revealed that this substance facilitates a water-splitting reaction leading to the generation of hydrogen when exposed to visible light which does not activate TiO2.

Since tin oxides are relatively non-toxic, inexpensive and abundant, they are widely used as transparent conductive materials. The discovery of the Sn3O4 catalyst is expected to greatly contribute to the reduction of environmental load and costs associated with hydrogen fuel production, and to the realization of a recycling-oriented society founded on the use of solar energy.

Results of this research will be published in the near future in the online version of Applied Materials & Interfaces, a journal issued by the American Chemical Society.

Associated links

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

A universal framework for spatial biology

SpatialData is a freely accessible tool to unify and integrate data from different omics technologies accounting for spatial information, which can provide holistic insights into health and disease. Biological processes…

How complex biological processes arise

A $20 million grant from the U.S. National Science Foundation (NSF) will support the establishment and operation of the National Synthesis Center for Emergence in the Molecular and Cellular Sciences (NCEMS) at…

Airborne single-photon lidar system achieves high-resolution 3D imaging

Compact, low-power system opens doors for photon-efficient drone and satellite-based environmental monitoring and mapping. Researchers have developed a compact and lightweight single-photon airborne lidar system that can acquire high-resolution 3D…