Saving Water without Hurting Peach Production

Agricultural Research Service (ARS) scientist James E. Ayars at the San Joaquin Valley Agricultural Sciences Center in Parlier, Calif., has found a way to reduce the amount of water given post-harvest to early-season peaches so that the reduction has a minimal effect on yield and fruit quality. ARS is USDA's principal intramural scientific research agency, and the research supports the USDA priority of promoting international food security.

The valley has about 25,000 acres of peach orchards that must be irrigated throughout the summer. Early-season peaches are normally harvested in May, but require most of their water from June through September, a time when temperatures and demands for water are at their highest. Snow packs in the Sierra Nevada have traditionally been a sufficient water source for growers, but earlier snowmelts have made water more precious with each summer. Wells that supply the valley have had to reach deeper to meet increasing demands.

Ayars and ARS scientist Dong Wang, also based at Parlier, irrigated a 4-acre plot of early-season peach trees from March to the May harvest. From June to September, they gave the trees either 25 percent of the amount of water they'd normally receive, 50 percent of the normal amount, or 100 percent. The scientists measured soil water content once a week to be sure that even with periodic rainfall, trees were given appropriate deficit-irrigation treatments. They also used three types of irrigation systems: microspray, subsurface drip irrigation, and furrow irrigation, in which water is distributed in shallow canal-like rows near the trees. Defective fruit were counted and removed after each harvest.

The results showed that reducing post-harvest irrigation levels to 25 percent of the normal amount had negative effects on yield and fruit quality, but that giving 50 percent less water than normal had minimal effects on the following year's quality and yield. The subsurface drip irrigation systems tended to have the lowest yields within a given year, but differences were generally not statistically significant. The researchers also found that trees needed less pruning and maintenance because the deficit irrigation slowed plant growth.

The results of this study have been submitted to the scientific journal HortScience for publication.

Read more about this research in the November/December 2012 issue of Agricultural Research magazine.

Media Contact

More Information:

http://www.ars.usda.govAll latest news from the category: Agricultural and Forestry Science

Newest articles

Targeted use of enfortumab vedotin for the treatment of advanced urothelial carcinoma

New study identifies NECTIN4 amplification as a promising biomarker – Under the leadership of PD Dr. Niklas Klümper, Assistant Physician at the Department of Urology at the University Hospital Bonn…

A novel universal light-based technique

…to control valley polarization in bulk materials. An international team of researchers reports in Nature a new method that achieves valley polarization in centrosymmetric bulk materials in a non-material-specific way…

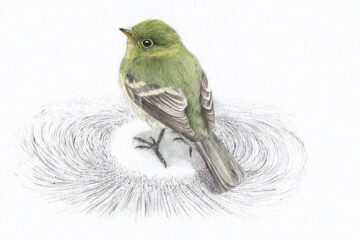

How evolution has optimised the magnetic sensor in birds

The magnetic sense of migratory birds is probably based on the protein cryptochrome 4, and a genetic study has now provided further support for this theory. A team of researchers…