Atom-Sized Craters Make a Catalyst Much More Active

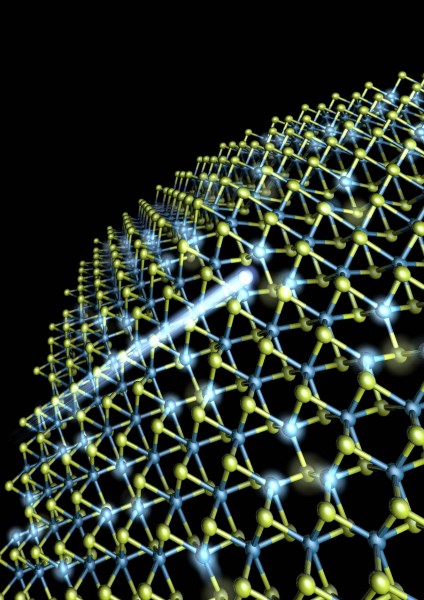

Charlie Tsai/ Stanford University Illustration of a catalyst being bombarded with argon atoms to create holes where chemical reactions can take place. The catalyst is molybdenum disulfide, or MoS2. The bombardment removed about one-tenth of the sulfur atoms (yellow) on its surface. Researchers then draped the holey catalyst over microscopic bumps to change the spacing of the atoms in a way that made the catalyst even more active.

Bombarding and stretching an important industrial catalyst opens up tiny holes on its surface where atoms can attach and react, greatly increasing its activity as a promoter of chemical reactions, according to a study by scientists at Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory.

The method could offer a much cheaper way to rev up the production of clean hydrogen fuel from water, the researchers said, and should also apply to other catalysts that promote useful chemical reactions. The study was published Nov. 9 in Nature Materials.

“This is just the first indication of a new effect, very much in the research stage,” said Xiaolin Zheng, an associate professor of mechanical engineering at Stanford who led the study. “But it opens up totally new possibilities yet to be explored.”

Finding a Cheap, Abundant Substitute

Catalysts are substances that promote chemical reactions without being consumed themselves, so they can be used over and over again. Natural catalysts are endlessly at work in plants, animals and our bodies. Industrial catalysts are used to make fuel, fertilizer and consumer products; they’re a multi-billion-dollar industry in their own right.

The catalyst studied here, molybdenum disulfide or MoS2, helps remove sulfur from petroleum in refineries. But scientists think it might also be a good alternative to platinum as a catalyst for a reaction that joins hydrogen atoms together to make hydrogen gas for fuel.

“We know platinum is very good at catalyzing this reaction,” said study co-author Jens Nørskov, director of the SUNCAT Center for Interface Science and Catalysis, a joint Stanford/SLAC institute. “But it’s a non-starter because of its rarity. There isn’t enough of it on Earth for large-scale hydrogen fuel production.”

MoS2 is much cheaper and made of abundant ingredients, and it comes in flexible sheets just one molecule thick, which are stacked together to make catalyst particles, Zheng said. All the catalytic action takes place on the edges of those sheets, where dangling chemical bonds can grab passing atoms and hold them together until they react.

Researchers have tried all sorts of schemes to increase the active area where this atomic matchmaking goes on. Most of them involve engineering the catalyst sheets to expose more edges, or adding chemicals to make the edges more active.

A Holey, Stretchy Solution

In the new approach, Stanford postdoctoral researcher Hong Li used an instrument in the Stanford Nanocharacterization Laboratory to bombard a sheet of MoS2 with argon atoms. This knocked about 1 out of 10 sulfur atoms out of the surface of the sheet, leaving holes surrounded by dangling bonds.

Then he stretched the holey sheet over microscopic bumps made of silicon dioxide coated with gold. He wet the sheet with a solvent, and when it dried the sheet was permanently deformed: The spacing of the atoms had changed in a way that made the holes much more chemically reactive.

“Before, the top surface of the sheet was not reactive. It was inert – zero, almost,” Zheng said. “Now the surface is more catalytically active than the edges. And we can tune this activity so the bonds that form on the catalyst are just right – strong enough to hold the reacting atoms in place, but weak enough so they’ll let go of the finished product once the atoms have joined together.”

SUNCAT theorists, including graduate student Charlie Tsai, played an important role in predicting which combinations of bombarding and stretching would produce the best results, using calculations made with SLAC supercomputers. The researchers said a combination of computation and experiment will be important in finding completely new kinds of active catalytic sites in the future.

Going forward, Zheng said, “We need to figure out how to do this in the layered catalytic particles that are used in industry, and whether we can apply the same idea to other catalytic materials.”

They’ll also need to find a better way to make the atom-sized holes, Tsai said. “Bombarding with argon is not practical,” he said. “The procedure is expensive, and it can’t really be scaled up for things like fuel production. So we’ve been working on a follow-up study where we try to replicate the results using a simpler process.”

Scientists from the Stanford Institute for Materials and Energy Research (SIMES) also played a key role in these experiments. The research was supported by the Samsung Advanced Institute of Technology (SAIT) and Samsung R&D Center America, Silicon Valley, and by SUNCAT and the Center on Nanostructuring for Efficient Energy Conversion at Stanford, both funded by the DOE Office of Science.

SLAC is a multi-program laboratory exploring frontier questions in photon science, astrophysics, particle physics and accelerator research. Located in Menlo Park, Calif., SLAC is operated by Stanford University for the U.S. Department of Energy's Office of Science. For more information, please visit slac.stanford.edu.

SLAC National Accelerator Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov

Contact Information

Andrew Gordon

External Communications Manager

agordon@slac.stanford.edu

Phone: 650-926-2282

Mobile: 510-325-9303

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Why getting in touch with our ‘gerbil brain’ could help machines listen better

Macquarie University researchers have debunked a 75-year-old theory about how humans determine where sounds are coming from, and it could unlock the secret to creating a next generation of more…

Attosecond core-level spectroscopy reveals real-time molecular dynamics

Chemical reactions are complex mechanisms. Many different dynamical processes are involved, affecting both the electrons and the nucleus of the present atoms. Very often the strongly coupled electron and nuclear…

Free-forming organelles help plants adapt to climate change

Scientists uncover how plants “see” shades of light, temperature. Plants’ ability to sense light and temperature, and their ability to adapt to climate change, hinges on free-forming structures in their…