New application of the selective laser melting method

Researchers of Peter the Great St. Petersburg Polytechnic University and Delft University of Technology obtained a gradient microstructure of the material and created a product, combining properties of two metals. Credit: Peter the Great St. Petersburg Polytechnic University

Scientists of Peter the Great St. Petersburg Polytechnic University (SPbPU) and Delft University of Technology developed a technology for obtaining new metal structures by selective laser melting method (additive technology of manufacturing three-dimensional objects from metal powders).

Key findings of the research have been described in an article “Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties” published in Materials & Design journal.

Due to this technology it is possible to obtain a gradient microstructure of the material and create a product, combining the properties of two metals. This material is characterized by high performance characteristics, such as temperature and pressure effects, strength, durability.

“This technology can be used for manufacturing of products operating in extreme conditions, such as high pressure and temperature,” says Vadim Sufiiarov, assistant professor of “Development, technologies and materials in aircraft engine building” department of the Institute of Metallurgy, Mechanical Engineering and Transport SPbPU.

“Therefore, this development can be applied for manufacturing of gas turbines elements for aviation, energy and marine,” adds Sufiiarov.

Generally, selective laser melting may be used to produce a fine-grained microstructure of the metal, which provides high mechanical properties at room temperature. However, the gases at combustion chamber exit of the gas turbine engine have the highest temperature and pressure. The gases aggressively act on the elements of the hot part of the turbine, primarily on blades and vanes, which are responsible for the rotor mechanism.

The first and second stage blades have the highest load, so they are not simply made using specially designed high-temperature alloys, but also form a special microstructure in the product. It is either single-crystal (when the product consists of one crystal and one grain type) or directionally crystallized (no grain boundaries in the transverse direction, all grain boundaries are located only along longitudinal direction).

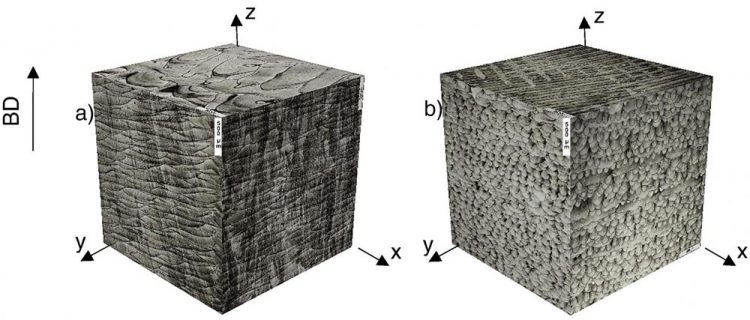

With the help of this technology it is possible to create both equiaxial structures, where the grains have approximately the same dimensions in all directions, as well as directionally crystallized grains and combine their arrangement in one product. Developed approach of additive technologies allows flexible control of material microstructure formation.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…