InLight study: insights into chemical processes using light

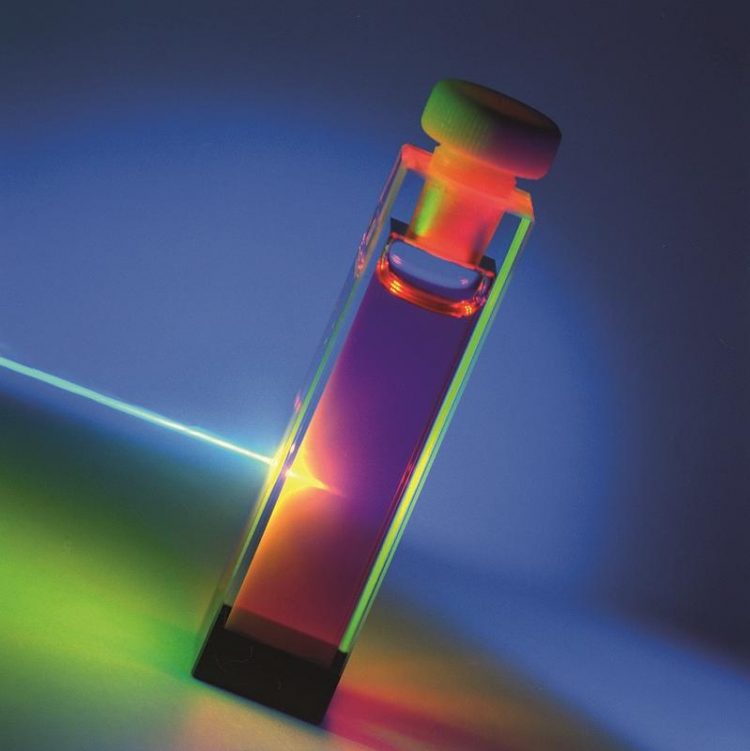

“Throwing light into the process”: Determination of chemical parameters by optical measurement through a vessel wall. Fraunhofer ILT, Aachen, Germany

Process analytical techniques – a promising sector

One of the keys to the success of chemical-physical and biotech production processes is the ability to measure critical process parameters accurately in-line. “Process analytical technology (PAT) is a good tool in this context, and one for which optical measuring techniques are particularly useful,” says Dr. Reinhard Noll, head of measurement technology and EUV sources at Fraunhofer ILT.

Making optical PAT suitable for harsh industrial environments rather than just the laboratory requires robust, automated sensor systems that fulfill the process requirements. With this goal in mind, the consortium led by Fraunhofer ILT investigated four key topics. The first was spectroscopic methods, which can be used even by people who have no specialist knowledge, and the team established that there are good development opportunities in this area. Their findings revealed considerable demand for versatile devices that can be used to measure parameters in the solid, liquid and gaseous aggregation states.

Optical access with no maintenance required

The second topic, optical access, focuses primarily on the vision of maintenance-free optical access. This topic also requires significant R&D investment in areas such as optical windows with integrated functional elements; for instance, smart windows.

The study team also came up with a tough set of requirements for the third topic, laser beam sources. These include affordable light sources (priced at < 1000 euros) for a wide range of applications (from mid-infrared to ultraviolet); they feature a long operating time (> 100,000 hours) and an extended range of operating temperatures.

Making sensor calibration simpler

Whether or not PAT systems succeed depends heavily on future progress in the fourth topic area: calibration, soft sensors and sensor fusion. The study team compiled a wish list that includes hugely simplified sensor calibration as well as the ability to transfer calibration settings from one device to another. The technology roadmap highlights different ways of meeting the team's medium- and long-term goals, including sensor fusion, self-diagnostics, automated sensor calibration and in situ qualification.

In early 2017, Fraunhofer ILT will be uploading a white paper to its website entitled “Optical process analytics – industry requirements, future perspectives and key R&D challenges.”

www.ilt.fraunhofer.de/en/projects-technology-studies

Detailed study: In-line process analytics with light – InLight

From October 2015 to October 2016, a consortium of experts led by Fraunhofer ILT carried out a detailed study of in-line process analytics with light. The team also included experts from the Berlin-based Federal Institute for Materials Research and Testing (BAM), RWTH Aachen University, and 14 companies from Germany and Austria.

Contact

PD Dr. rer. nat. Reinhard Noll

Head of the Competence Area Measurement Technology and EUV Sources

Phone +49 241 8906-138

reinhard.noll@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de

http://www.ilt.fraunhofer.de/en/projects-technology-studies

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Trotting robots reveal emergence of animal gait transitions

A four-legged robot trained with machine learning by EPFL researchers has learned to avoid falls by spontaneously switching between walking, trotting, and pronking – a milestone for roboticists as well…

Innovation promises to prevent power pole-top fires

Engineers in Australia have found a new way to make power-pole insulators resistant to fire and electrical sparking, promising to prevent dangerous pole-top fires and reduce blackouts. Pole-top fires pose…

Possible alternative to antibiotics produced by bacteria

Antibacterial substance from staphylococci discovered with new mechanism of action against natural competitors. Many bacteria produce substances to gain an advantage over competitors in their highly competitive natural environment. Researchers…