Elucidating the Atomic Mechanism of Superlubricity

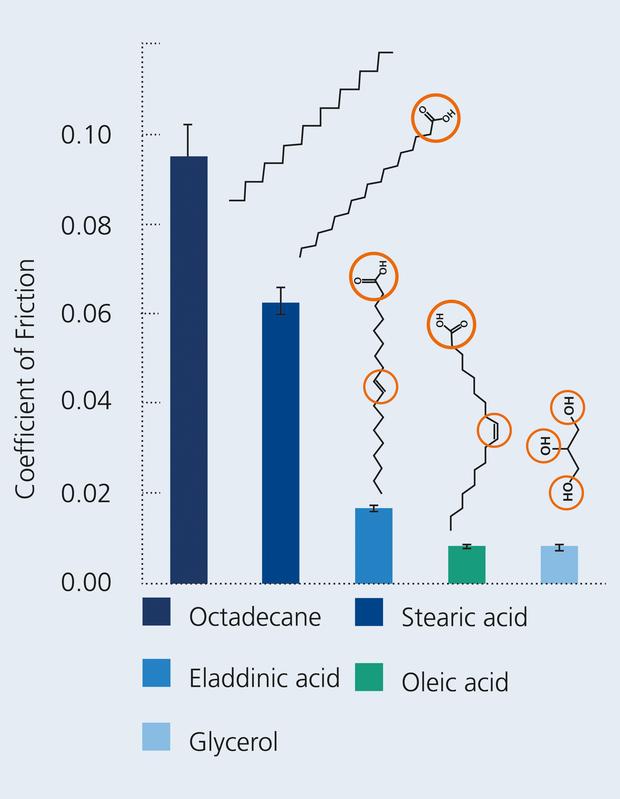

A ta-C coated steel pin oscillates while rubbing on a ta-C coated steel disc: the friction depends significantly on the amount of reactive lubricant centers (red circles). © Fraunhofer Institute for Material and Beam Technology IWS

One of the most important prerequisites for sustainable and environmentally friendly mobility is minimizing friction. Research and industry have been dedicated to this important project for years.

Superlubricity could achieve not only minor, but also extreme friction reductions. If, for example, friction in the engines and transmissions of vehicles is reduced to minimum values, such as those occurring with superlubricity, annual global CO2 emissions could be reduced by several hundred million tons.

Two Fraunhofer Institutes have taken an important step toward this vision. In the PEGASUS II project funded by the Federal Ministry of Economics and Energy (BMWi), scientists from the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg and the Fraunhofer Institute for Material and Beam Technology IWS in Dresden have uncovered the atomic mechanism underlying superlubricity in a special friction partner system.

They investigated promising tribological systems in which the friction partners’ surfaces consist of special diamond-like carbon layers produced with a coating technology developed at the Fraunhofer IWS. These so-called tetrahedral amorphous carbon layers (ta-C) were combined with organic lubricants. Using simulations, the research team found out that the lubricant decomposes tribochemically to form graphene-like surfaces: the prerequisite for superlubricity.

Atomic Prerequisites for Supra Lubrication

Dr. Volker Weihnacht, Head of Carbon Layer Department, and Stefan Makowski, Group Leader Coating Properties at Fraunhofer IWS, systematically investigated the interaction of lubricants with ta-C carbon surfaces. Unsaturated fatty acids or glycerol achieved extremely low coefficients of friction at the superlubricity level.

They were astonished by two things: that this effect did not occur with the smallest changes in the molecular structure and that the friction was much higher. Thus, saturated fatty acids and alkanes did not achieve a superlubricity effect.

Prof. Michael Moseler and Dr. Gianpietro Moras at the Fraunhofer IWM explained the reason for this: “Using quantum chemical simulations, we were able to demonstrate that lubricant molecules with at least two reactive centers are able to form a chemical bond simultaneously with both ta-C-coated surfaces and are torn apart by the sliding motion and broken down into their constituent parts,” explains Prof. Moseler, head of the “Multiscale Modeling and Tribosimulation” group.

This allows for the release of the lubricant’s oxygen atoms and for these to be incorporated into the ta-C film. The oxygen disturbs the three-dimensional tetrahedral carbon network and aids in the formation of graphene-like surfaces, which effectively suppress friction as well as wear and thus ensure superlubricity.

Corresponding simulations with alkanes or saturated fatty acids as lubricants did not show these mechano-chemical processes because they have no or only one reactive center. “These lubricants only adhere to one surface and form a molecular brush – which reduces friction, but not at the superlubricity level,” says Prof. Moseler.

The newly discovered design rule states that several reactive centers must be present in the lubricant to cause superlubricity. “Of course, this rule is not limited to the fatty acids investigated here, it can also be transferred to other lubricants,” Prof. Moseler adds.

Guidelines for the Novel Lubricants’ Design

The research team’s results allow both predicting tribological properties of ta-C surfaces lubricated with different molecule types and forming guidelines for the novel organic friction modifiers’ design. Predictions for tailoring the carbon layers themselves and the necessary supra lubricant design rules for other surfaces, such as steel or aluminum, also become conceivable projects.

In 2019, the scientists at the Fraunhofer IWM and IWS will continue to work with industrial partners on translating quantum chemical findings into engineering solutions as part of the PROMETHEUS project with financial support from BMWi. Their goal: further reducing friction in combustion engines as well as other applications.

Additional: Details of the Superlubricity

In superlubricity, friction is extremely low with a friction coefficient µ of less than 0.01. The surfaces of tetrahedral hydrogen-free amorphous carbon layers (ta-C) and the most efficient lubrication possible with unsaturated fatty acids or glycerol compounds are promising for a friction system with minimal friction.

Quantum chemical simulations have shown that lubricant molecules, which can form a chemical bond simultaneously with both ta-C-coated surfaces, are torn apart by the sliding motion and broken down into their components. This mechano-chemical fragmentation leads to oxygen ta-C films doping – an important prerequisite for the in-situ synthesis of graphene-like surfaces effectively suppressing friction and wear.

Forming these supralubricating layers therefore requires the lubricant to have several reactive centers causing its mechano-chemical fragmentation. Unsaturated fatty acids feature a double bond and a carboxyl group as reactive centers, while glycerol possesses three reactive hydroxyl groups.

Prof. Dr. Michael Moseler l Phone +49 761 5142-332 l michael.moseler@iwm.fraunhofer.de | Fraunhofer Institute for Mechanics of Materials IWM, Freiburg l www.iwm.fraunhofer.de

Dr. Volker Weihnacht l Phone +49 351 83391-3247 l volker.weihnacht@iws.fraunhofer.de | Fraunhofer Institute for Material and Beam Technology IWS , Dresden l www.iws.fraunhofer.de

Kuwahara, T.; Romero, P.A.; Makowski, S.; Christmas, V.; Moras, G.; Moseler, M.; Mechano-chemical decomposition of organic friction modifiers with multiple reactive centres induces superlubricity of ta-C, Nature Communications 10 (2019) Artikelnummer, DOI 10.1038/s41467-018-08042-8

https://doi.org/10.1038/s41467-018-08042-8 – Link to the article

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…