Capturing 3D microstructures in real time

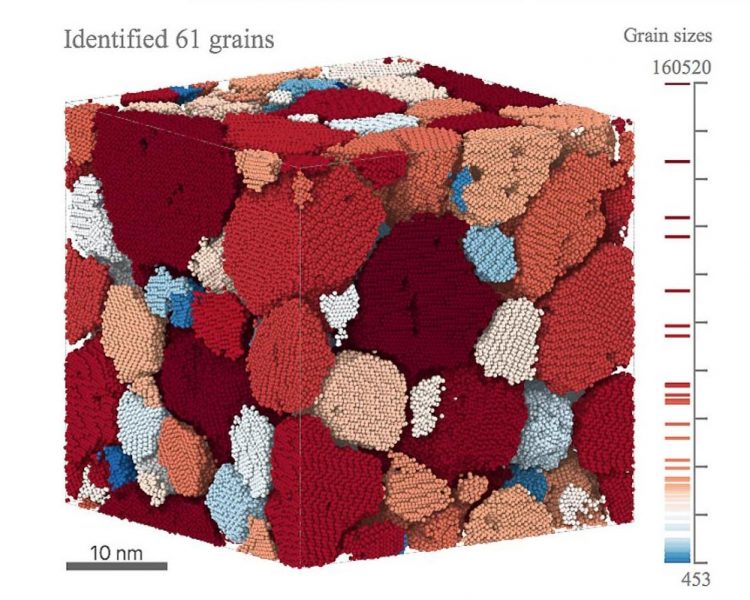

Machine-learning enabled characterization of 3D microstructure showing grains of different sizes and their boundaries. Credit: Argonne National Laboratory

Researchers at the Center for Nanoscale Materials (CNM), a U.S. Department of Energy (DOE) Office of Science User Facility located at the DOE's Argonne National Laboratory, have invented a machine-learning based algorithm for quantitatively characterizing, in three dimensions, materials with features as small as nanometers. Researchers can apply this pivotal discovery to the analysis of most structural materials of interest to industry.

“What makes our algorithm unique is that if you start with a material for which you know essentially nothing about the microstructure, it will, within seconds, tell the user the exact microstructure in all three dimensions,” said Subramanian Sankaranarayanan, group leader of the CNM theory and modeling group and an associate professor in the Department of Mechanical and Industrial Engineering at the University of Illinois at Chicago.

“For example, with data analyzed by our 3D tool,” said Henry Chan, CNM postdoctoral researcher and lead author of the study, “users can detect faults and cracks and potentially predict the lifetimes under different stresses and strains for all kinds of structural materials.”

“What makes our algorithm unique is that if you start with a material for which you know essentially nothing about the microstructure, it will, within seconds, tell the user the exact microstructure in all three dimensions.” — Subramanian Sankaranarayanan, CNM group leader and associate professor at the University of Illinois at Chicago

Most structural materials are polycrystalline, meaning a sample used for purposes of analysis can contain millions of grains.

The size and distribution of those grains and the voids within a sample are critical microstructural features that affect important physical, mechanical, optical, chemical and thermal properties. Such knowledge is important, for example, to the discovery of new materials with desired properties, such as stronger and harder machine components that last longer.

In the past, scientists have visualized 3D microstructural features within a material by taking snapshots at the microscale of many 2D slices, processing the individual slices, and then pasting them together to form a 3D picture.

Such is the case, for example, with the computerized tomography scanning routine done in hospitals. That process, however, is inefficient and leads to the loss of information. Researchers have thus been searching for better methods for 3D analyses.

“At first,” said Mathew Cherukara, an assistant scientist at CNM, “we thought of designing an intercept-based algorithm to search for all the boundaries among the numerous grains in the sample until mapping the entire microstructure in all three dimensions, but as you can imagine, with millions of grains, that is extraordinarily time-consuming and inefficient.”

“The beauty of our machine learning algorithm is that it uses an unsupervised algorithm to handle the boundary problem and produce highly accurate results with high efficiency,” said Chan. “Coupled with down-sampling techniques, it only takes seconds to process large 3D samples and obtain precise microstructural information that is robust and resilient to noise.”

The team successfully tested the algorithm by comparison with data obtained from analyses of several different metals (aluminum, iron, silicon and titanium) and soft materials (polymers and micelles).

These data came from earlier published experiments as well as computer simulations run at two DOE Office of Science User Facilities, the Argonne Leadership Computing Facility and the National Energy Research Scientific Computing Center. Also used in this research were the Laboratory Computing Resource Center at Argonne and the Carbon Cluster in CNM.

“For researchers using our tool, the main advantage is not just the impressive 3D image generated but, more importantly, the detailed characterization data,” said Sankaranarayanan. “They can even quantitatively and visually track the evolution of a microstructure as it changes in real time.”

The machine-learning algorithm is not restricted to solids. The team has extended it to include characterization of the distribution of molecular clusters in fluids with important energy, chemical and biological applications.

This machine-learning tool should prove especially impactful for future real-time analysis of data obtained from large materials characterization facilities, such as the Advanced Photon Source, another DOE Office of Science User Facility at Argonne, and other synchrotrons around the world.

###

This study, titled “Machine learning enabled autonomous microstructural characterization in 3D samples,” appeared in npj Computational Materials. In addition to Sankaranarayanan and Chan, authors include Mathew Cherukara, Troy D. Loeffler, and Badri Narayanan. This study received funding from the DOE Office of Basic Energy Sciences.

About Argonne's Center for Nanoscale Materials

The Center for Nanoscale Materials is one of the five DOE Nanoscale Science Research Centers, premier national user facilities for interdisciplinary research at the nanoscale supported by the DOE Office of Science. Together the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process, characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE's Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge, Sandia and Los Alamos National Laboratories. For more information about the DOE NSRCs, please visit https:/

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy's Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https:/

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Trotting robots reveal emergence of animal gait transitions

A four-legged robot trained with machine learning by EPFL researchers has learned to avoid falls by spontaneously switching between walking, trotting, and pronking – a milestone for roboticists as well…

Innovation promises to prevent power pole-top fires

Engineers in Australia have found a new way to make power-pole insulators resistant to fire and electrical sparking, promising to prevent dangerous pole-top fires and reduce blackouts. Pole-top fires pose…

Possible alternative to antibiotics produced by bacteria

Antibacterial substance from staphylococci discovered with new mechanism of action against natural competitors. Many bacteria produce substances to gain an advantage over competitors in their highly competitive natural environment. Researchers…