Stronger than steel

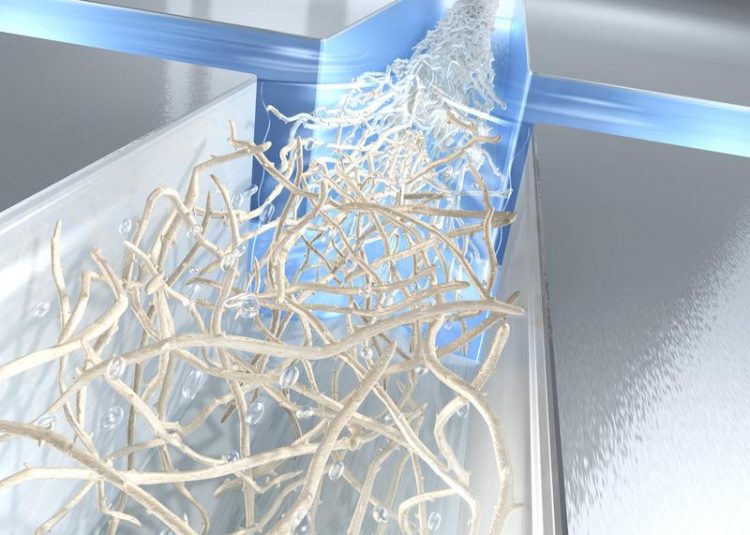

Artist's impression of the production of ultra-strong cellulose fibers: The cellulose nano fibrils flow through a water channel and become accelerated by the inflow of additional water jets from the sides. The acceleration lets all fibrils align with the direction of flow, finally locking together as a strong fiber. Credit: Credit: DESY/Eberhard Reimann

A Swedish-German research team has successfully tested a new method for the production of ultra-strong cellulose fibres at DESY's research light source PETRA III. The novel procedure spins extremely tough filaments from tiny cellulose fibrils by aligning them all in parallel during the production process. The new method is reported in the scientific journal Nature Communications.

“Our filaments are stronger than both aluminium and steel per weight,” emphasizes lead author Prof. Fredrik Lundell from the Wallenberg Wood Science Center at the Royal Swedish Institute of Technology KTH in Stockholm. “The real challenge, however, is to make bio based materials with extreme stiffness that can be used in wind turbine blades, for example. With further improvements, in particular increased fibril alignment, this will be possible.”

For their method, the researchers took tiny, nanometre-sized cellulose fibrils and fed them together with water through a small channel. Two additional water jets coming in perpendicular from left and right accelerate the fibril flow. “Following the acceleration, all nano fibrils align themselves more or less parallel with the flow,” explains co-author Dr. Stephan Roth from DESY, head of the experimental station P03 at PETRA III where the experiments took place. “Furthermore, salt is added to the outer streams. The salt makes the fibrils attach to each other, thereby locking the structure of the future filament.”

Finally, the wet filaments are left to dry in air where they shrink to form a strong fibre. “Drying takes a few minutes in air,” explains co-author Dr. Daniel Söderberg from KTH. “The resulting material is completely compatible with the biosphere, since the natural structure of the cellulose is maintained in the fibrils. Thus, it is biodegradable and compatible with human tissue.”

The bright X-ray light from PETRA III enabled the scientists to follow the process and check the configuration of the nano fibrils at various stages in the flow. “Research today is driven by cross-disciplanary collaborations,” underlines Söderberg. “Without the excellent competence and possibilities brought into the project by the team of DESY's experimental station P03 this would not have been possible.”

As the scientists write, their fibres are much stronger than all other previously reported artificial filaments from cellulose nano fibrils. In fact, the artificial filaments can rival the strongest natural cellulose pulp fibres extracted from wood at the same degree of alignment of the nano fibrils. “In principle, we can make very long fibres,” says Lundell. “Up until now we have made samples that where ten centimetres long or so, but that is more of an equipment issue than a fundamental problem.”

For their experiments, the researchers have used nano fibrils extracted from fresh wood. “In principle, it should be possible to obtain fibrils from recycled paper also,” says Lundell. But he cautions: “The potential of recycled material in this context needs further investigations.”

Deutsches Elektronen-Synchrotron DESY is the leading German accelerator centre and one of the leading in the world. DESY is a member of the Helmholtz Association and receives its funding from the German Federal Ministry of Education and Research (BMBF) (90 per cent) and the German federal states of Hamburg and Brandenburg (10 per cent). At its locations in Hamburg and Zeuthen near Berlin, DESY develops, builds and operates large particle accelerators, and uses them to investigate the structure of matter. DESY's combination of photon science and particle physics is unique in Europe.

Reference

“Hydrodynamic alignment and assembly of nano-fibrils resulting in strong cellulose filaments”; Karl M. O. Håkansson, Andreas B. Fall, Fredrik Lundell, Shun Yu, Christina Krywka, Stephan V. Roth, Gonzalo Santoro, Mathias Kvick, Lisa Prahl Wittberg, Lars Wågberg & L. Daniel Söderberg; Nature Communications, 2014; DOI: 10.1038/ncomms5018

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Red light therapy for repairing spinal cord injury passes milestone

Patients with spinal cord injury (SCI) could benefit from a future treatment to repair nerve connections using red and near-infrared light. The method, invented by scientists at the University of…

Insect research is revolutionized by technology

New technologies can revolutionise insect research and environmental monitoring. By using DNA, images, sounds and flight patterns analysed by AI, it’s possible to gain new insights into the world of…

X-ray satellite XMM-newton sees ‘space clover’ in a new light

Astronomers have discovered enormous circular radio features of unknown origin around some galaxies. Now, new observations of one dubbed the Cloverleaf suggest it was created by clashing groups of galaxies….