Why Nanolayers Buckle when Microbeams Bend

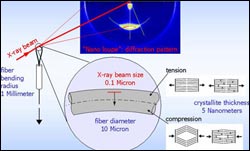

An x-ray beam just 100 nanometres in width functions as a "nano-magnifier" to explore, in detail, defects and changes in carbon fibres. Image: Max Planck Institute of Colloids and Interfaces

German-Austrian-French research team uses a hundred-nanometre wide x-ray beam to observe how nanolayers buckle in bent high-tech carbon fibres

Scientists from the Max Planck Institute of Colloids and Interfaces, working together with colleagues from the University of Vienna and the European Synchrotron Radiation Facility in Grenoble, France have made the first-ever observations of nanocrystallite buckling in carbon fibres. The results indicate that missing cross-links between the individual carbon layers are responsible for the buckling. (Physical Review Letters, November 25, 2005). Such a finding has implications for the way high-tech carbon materials are produced.

High-strength, ultra-light and elastic carbon materials are commonly used in high-performance sports goods and modern aerospace technology – for example in tennis rackets, racing tyres, heat shields and even guitars. Carbon fibres are only a few micrometres thick and mainly used to mechanically reinforce other materials, like polymers, metals, and ceramics. In tension, these kinds of fibres are stronger than most other known materials. However, compression applied parallel to the fibre axis can cause the buckling of nanoscale carbon layers – comparable to the buckling of a long, thin rod under compressive load.

In a novel physical experiment at the European Synchrotron Radiation Facility in Grenoble, researchers from Potsdam, Germany and Vienna have threaded both ends of micrometre thick carbon fibres through thin hollow needles in order to form fibre loops. The fibres are stretched on the outside of the loop and compressed on the inside. In-between there is a neutral zone, as we might find in a bent beam. By tugging on the ends of the fibres, the scientists were able to adjust the loop’s radius, and thus also the mechanical load in the tensile and the compression region. Oskar Paris from the Max Planck Institute of Colloids and Interfaces explains that “what is unique about the experiment is that we can make observations at many length-scales and thus gather evidence about the secret of ‘nano-buckling’. Using a 100-nanometre wide x-ray beam, we can scan the differently distorted regions along the cross-section of the fibre. Our nano-magnifier – the diffraction of the x-ray beam -allows us to measure the local strains of the only some nanometres thick carbon layers, as well as their orientation with respect to the fibre axis.”

High-tech carbon fibres are made of graphite-like carbon sheets with strong covalent atomic bonding within the sheets, and weak Van der Waals bonding between them. Almost all the physical properties – and particularly mechanical behaviour – of these materials depend on their orientation. Their tensile stiffness is as much as five times higher than that of steel, and their specific tensile strength can overcome that of steel by a factor of ten. Under compression, however, the fibres can fail. Here, the mechanical behaviour is determined by mechanical instability – carbon layers buckling at the nanoscale – in addition to the shearing of single carbon layers.

In spite of this, some carbon fibres exhibit astoundingly good shear properties. In these cases, “nano-buckling” is rarely observed – which suggests the existence of a substantial number of strong cross-links between the carbon layers. Herwig Peterlik from the University of Vienna explains that “if we could reinforce the usually very weak connections between the carbon layers in a controlled way using this kind of covalent cross-links, then in addition to carbon fibres, the highly-vaunted new carbon nanotubes would be almost ready to make the strongest ropes in the world.”

This has been possible very recently with electron irradiation, which requires however a high expenditure of money and energy. The high price is also the major reason why carbon fibres, which are relatively cheap to produce, are not easily replaced by modern nanotubes. The question why these valuable cross-links occur only in some carbon fibres, while others buckle, still remains unclear.

[EC]

Original work:

Dieter Loidl, Oskar Paris, Manfred Burghammer, Christian Riekel and Herwig Peterlik

Direct observation of nanocrystallite buckling in carbon fibers under bending load

Physical Review Letters 95, 225501 (2005), November 2005

Media Contact

More Information:

http://www.mpg.deAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…