Light scattering method reveals details under skin

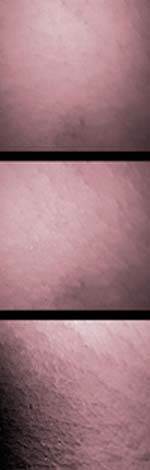

The colorized photos above show two images of pigskin taken under different lighting conditions (top and middle) that were combined by NIST and Johns Hopkins researchers to reveal greater subsurface detail (bottom).

A new optical method that can image subsurface structures under skin has been demonstrated by scientists at the National Institute of Standards and Technology (NIST) and the Johns Hopkins University Applied Physics Laboratory.

The method relies on differences in the way surface and subsurface features of various materials scatter light. It was demonstrated with small pieces of pigskin and inorganic materials but might eventually prove useful for imaging living tissues to help diagnose or determine the extent of various types of skin cancers. A paper on the work was presented at a recent technical meeting and is in press.*

The imaging process involves illuminating a sample with polarized light, which has its electric field oriented in a particular direction, and using a digital camera with a rotating polarization filter to image the light scattered from the sample. Researchers manipulated the polarization to minimize light scattered from the rough skin surface, and positioned the light source in multiple locations to separate out, and delete, light scattered more than one time from deeper sample layers. By using certain polarization settings and combining two images made with the light source in different positions, they generated a processed image that reveals significant subsurface structure.

Polarized light imaging already is used in dermatology to identify the edges of lesions. The new method minimizes the effects of two types of unwanted light scattering at once, and thus, if confirmed by other methods, might someday be used in a clinical setting to produce more detailed images of deeper layers of skin.

The method was developed under a Cooperative Research and Development Agreement between the two institutions. The project adapted light scattering techniques originally developed by NIST researchers to image surface and subsurface features in inorganic materials such as silicon wafers, mirrors and paint coatings. Scientists currently are working on making the new method easier and faster to use.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Red light therapy for repairing spinal cord injury passes milestone

Patients with spinal cord injury (SCI) could benefit from a future treatment to repair nerve connections using red and near-infrared light. The method, invented by scientists at the University of…

Insect research is revolutionized by technology

New technologies can revolutionise insect research and environmental monitoring. By using DNA, images, sounds and flight patterns analysed by AI, it’s possible to gain new insights into the world of…

X-ray satellite XMM-newton sees ‘space clover’ in a new light

Astronomers have discovered enormous circular radio features of unknown origin around some galaxies. Now, new observations of one dubbed the Cloverleaf suggest it was created by clashing groups of galaxies….