NASA's Phoenix Mars Lander Testing Sprinkle Technique

“We're a little surprised at how much this material is clumping together when we dig into it,” said Doug Ming a Phoenix science team member from NASA's Johnson Space Center, Houston.

The soil's physical properties are proving to be a challenge for getting a sample intended for one instrument to pass through a screen over a delivery opening.The instrument is the Thermal and Evolved-Gas Anaylzer, or TEGA, designed to bake and sniff samples to identify some key ingredients. The analyzer vibrated the screen for 20 minutes on Sunday but detected only a few particles getting through the screen, not enough to fill the tiny oven below.

“We are going to try vibrating it one more time, and if that doesn't work, it is likely we will use our new, revised delivery method on another thermal analyzer cell,” said William Boynton of the University of Arizona, lead scientist for the instrument.

The arm delivered the first sample to TEGA on Friday by turning the scoop over to release its contents. The revised delivery method, which Phoenix is testing for the first time today, will hold the scoop at an angle above the delivery target and sprinkle out a small amount of the sample by vibrating the scoop.

The vibration comes from running a motorized rasp on the bottom of the scoop.

Phoenix used the arm Sunday to collect a soil sample for the spacecraft's Optical Microscope. Today's plans include a practice of the sprinkle technique, using a small amount of soil from the sample collected Sunday. If that goes well, the Phoenix team assembled at the University of Arizona plans to sprinkle material from the same scoopful onto the microscope later this week.

The Phoenix mission is led by Peter Smith at the University of Arizona with project management at JPL and development partnership at Lockheed Martin, Denver. International contributions come from the Canadian Space Agency; the University of Neuchatel, Switzerland; the universities of Copenhagen and Aarhus, Denmark; Max Planck Institute, Germany; and the Finnish Meteorological Institute.

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

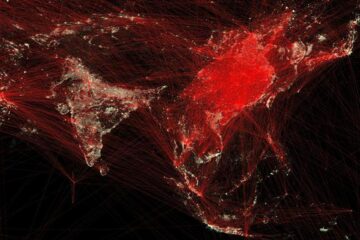

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

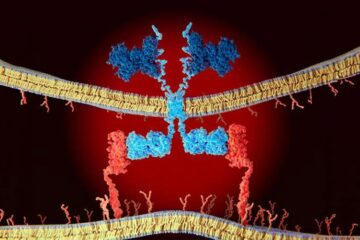

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…