Breakthrough in superconducting materials opens new path to fusion

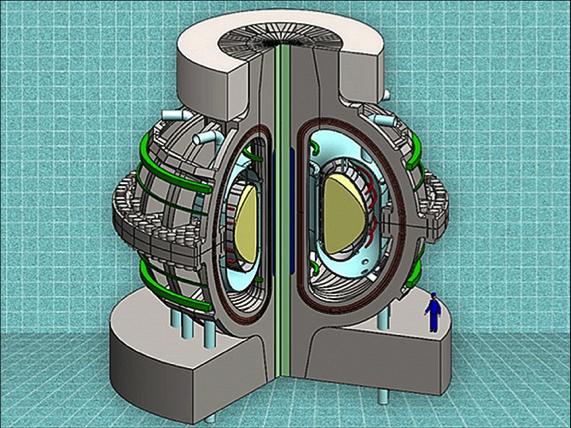

Conceptual design of the ARC fusion reactor. About the same size as the currently operating JET tokamak in the United Kingdom, but with three times the magnetic field strength, ARC is sized to produce 500 MW of deuterium-tritium fueled fusion power. Credit: Earl Marmar

In fusion reactor designs, superconductors (which suffer no resistive power loss) are used to generate the magnetic fields that confine the 100 million degree C plasma.

While increasing magnetic field strength offers potential ways to improve reactor performance, conventional low-temperature superconductors suffer dramatic drops in current carrying ability at high magnetic fields. Now, the emergence of high-temperature superconductors that can also operate at high magnetic fields opens a new, lower-cost path to fusion energy.

A typical measure of fusion plasma performance is called “plasma beta,” which is the ratio of plasma pressure to magnetic field pressure. Achieving a very high beta–generating the required plasma pressure with low magnetic field–could help reduce the cost of the superconducting magnets used in a fusion reactor.

For this reason, many visions of fusion reactors try to maximize plasma beta at moderate magnetic field strengths. Operation at higher beta, however, pushes the plasma up against many performance limits, making plasma stability a tricky business.

But plasma beta is not the only consideration. Another ratio, the size of the confined plasma compared to the ion gyroradius, also determines overall energy confinement and dictates plasma performance. (The ion gyroradius is the helical path ions are forced to follow in the magnetic field.)

Increasing magnetic field strength decreases the ion gyroradius, which allows a reduction in the size of the fusion device with no loss of performance. This approach also lowers beta and the plasma operates farther away from stability limits, in a “safe zone.”

While scientists have explored both of these paths to improving performance, the recent development of the so-called “high-temperature superconductors” opens a window for much higher magnetic fields, as the critical currents do not degrade rapidly, even at magnetic field values of 30 Tesla or higher. So these should really be called high-temperature, high-magnetic-field superconductors.

For tokamak design, the field strength limits are primarily determined by the maximum allowable stresses in the structural components holding the magnet together, and not by the intrinsic limits of the superconductors.

Even the most aggressive tokamak designs with conventional superconductor technology are limited to about 6 Tesla on-axis toroidal magnetic fields. By nearly doubling magnetic field strength, to about 10 Tesla on-axis, conceptual designs indicate that a tokamak approximately the physical size of the world's largest currently operating tokamak, JET, would be capable of producing 500 MW of fusion power, and even net electricity (Figure 1).

High-temperature, high-magnetic-field superconductors can also make it possible to incorporate jointed magnetic coils into the reactor design, dramatically improving flexibility, and ultimately, maintainability for reactor systems.

While several physics and technology challenges remain to be solved, the world-wide experience from tokamak experiments provides the basis to support a new path of exploration into compact, power producing reactors using the newly available high-temperature, high-magnetic-field superconducting technology.

###

Contact: Earl Marmar, (617) 253-5455, marmar@psfc.mit.edu

Abstracts: JT2.00001 Considerations of the high magnetic field tokamak path on the approach to fusion energy

Session Session JT2: Tutorial: Considerations of the High Magnetic Field Tokamak Path on the Approach to Fusion Energy

2:00 PM-3:00 PM, Tuesday, November 17, 2015

Room: Chatham Ballroom C

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Why getting in touch with our ‘gerbil brain’ could help machines listen better

Macquarie University researchers have debunked a 75-year-old theory about how humans determine where sounds are coming from, and it could unlock the secret to creating a next generation of more…

Attosecond core-level spectroscopy reveals real-time molecular dynamics

Chemical reactions are complex mechanisms. Many different dynamical processes are involved, affecting both the electrons and the nucleus of the present atoms. Very often the strongly coupled electron and nuclear…

Free-forming organelles help plants adapt to climate change

Scientists uncover how plants “see” shades of light, temperature. Plants’ ability to sense light and temperature, and their ability to adapt to climate change, hinges on free-forming structures in their…