New ’implanted contacts’ designed to fix nearsightedness

UT Southwestern Medical Center ophthalmologists will be the first in the area to insert a new type of implanted lens to fix nearsightedness.

“Think of it as a contact lens inside your eye,” said Dr. Wayne Bowman, who is inserting the new implantable collamer lens, or ICL, today for the first time at UT Southwestern University Hospitals.

The ICL can replace or reduce the need for glasses by permanently placing the specially fitted artificial lens in front of the eye’s natural lens, rather than replacing the natural lens as other implanted lens do, said Dr. Bowman, professor of ophthalmology.

The lens, made of a special collamer material, corrects moderate to severe nearsightedness, known as myopia, by bending light rays to improve blurry distance vision without the need for glasses or contacts.

Dr. Bowman said the lens currently is approved only for nearsightedness, but it may eventually be available for farsightedness and astigmatism. It has been used for nearsightedness for several years in Europe and was approved by the Food and Drug Administration in December.

According to the FDA, a clinical study of 294 implanted patients showed that 95 percent — 279 patients — had 20/40 or better vision, which is considered the standard needed for an unrestricted driver’s license. And 59 percent — almost 175 patients — had 20/20 or better vision after three years.

Ideal candidates are typically under 40 years of age and don’t yet have presbyopia, which makes reading glasses necessary, and whose corrections are outside the parameters for routine laser procedures, said Dr. Steven Verity, associate professor of ophthalmology, who specializes in refractive corneal surgery.

Rather than reshaping the eye, as in laser surgery, or replacing the eye’s natural lens, as with intraocular lenses, the collamer lens is inserted with a smaller incision. The lens is like a fixed contact, but it can be removed if need be.

The procedure, Dr. Bowman said, normally takes about 10 to 15 minutes, and the patient sees the improvement soon after.

The Visian implantable lens is made by STAAR Surgical Co. in Monrovia, Calif.

Media Contact

More Information:

http://www.utsouthwestern.eduAll latest news from the category: Health and Medicine

This subject area encompasses research and studies in the field of human medicine.

Among the wide-ranging list of topics covered here are anesthesiology, anatomy, surgery, human genetics, hygiene and environmental medicine, internal medicine, neurology, pharmacology, physiology, urology and dental medicine.

Newest articles

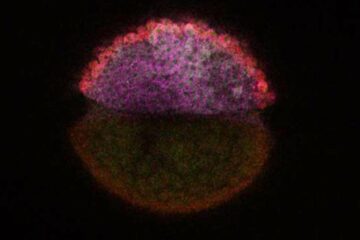

Decoding development: mRNA’s role in embryo formation

A new study at Hebrew University reveals insights into mRNA regulation during embryonic development. The study combines single-cell RNA-Seq and metabolic labeling in zebrafish embryos, distinguishing between newly-transcribed and pre-existing…

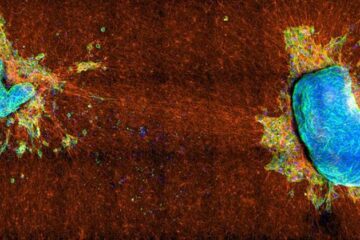

Study sheds light on cancer cell ‘tug-of-war’

How cancer cells tug against each other determines whether they can migrate elsewhere in the body. Understanding how cancerous cells spread from a primary tumor is important for any number…

Latest generation of self-dissolving stents

Magnesium implants support coronary arteries and keep them open. Constricted coronary arteries harbor dangers: Because the heart is not supplied with blood properly, this can lead to pain, cardiac arrhythmia,…