Monitoring Life, One Breath At A Time

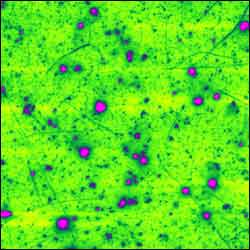

Atomic force microscopy (AFM) image of the carbon nanotube network device coated with poly(ethylene imine) and starch polymer layer for detection of CO2 gas Credit: Vikram Joshi, Nanomix

Respiratory sensor may provide new tool for emergency responders

Researchers have created a tiny device that can monitor a victim’s breathing in emergency situations by effectively shrinking an operating room machine into a small, disposable tool that can be carried to a disaster site.

NSF-supported researchers at Nanomix, Inc., in Emeryville, Calif., have created a transistor that fuses carbon nanotubes, polymers and silicon into a capnography sensor — a human breathing monitor.

Alexander Star and his colleagues at Nanomix and the University of California, Los Angeles, describe the new sensor in the cover article of the November 15 issue of the journal Advanced Materials. Their study shows that carbon nanotube transistors fused with carbon dioxide-detecting polymers can determine carbon dioxide (CO2) concentrations in both ambient and exhaled air.

Capnography sensors detect subtle changes in the concentration of carbon dioxide gas in a person’s breath, revealing respiratory diseases in children and adults, and allowing anesthesiologists to monitor a patient’s breathing during surgery.

In the field, emergency responders may be able to use the new sensor to verify proper breathing tube placement, monitor the patient’s respiratory patterns and assess the effect of life support measures.

While the Nanomix device is already capable of monitoring human breathing in laboratory settings, the researchers are collaborating with anesthesiologists and other specialists at the University of California, San Francisco, to design and test a field-ready medical device.

The Nanomix researchers developed their nanotube transistor as part of NSF’s Small Business Innovation Research program, and they are also applying the new technology to optoelectronic memory applications.

The same electronic interactions between polymers and carbon nanotubes that sense CO2 can also yield photo-sensitive devices that record the binary “on” and “off” patterns of digital memory. The memory is written optically, but read and erased electronically.

When researchers shine light on the polymer-coated nanotube transistors, electric signals are stored as charges in the nanotubes. Because different polymers absorb light differently, engineers can tune the device to work under specific light waves. By changing the voltage in the device, one can control the read and erase functions.

These research results, which were published in the September issue of Nano Letters, differ from other memory and optical applications of nanotube transistors.

Comments from the researchers:

“We have developed nanoelectronic sensors that accurately measure carbon dioxide in human breath. This sensing technology will break new ground in the development of medical devices that take advantage of the unique qualities of nanotechnology – small size, low power and high sensitivity.” — Alexander Star, Manager, Applications Development, Nanomix, Inc. “We are using two-layer nanodevice assembly, which allows us to control each component to change the operation of the devices. While the nanotube layer defines the density and complexity of nanodevice arrays on the chip, we can independently fine-tune the devices by using different polymers.” — Alexander Star

Comments from UCSF:

“Being able to continuously and accurately measure carbon dioxide in exhaled breath with a small, inexpensive and pre-calibrated device is a very significant development in clinical care. It will improve emergency care in the field by helping guide resuscitation efforts and also provide important feedback about adequacy of ventilation. ” — Philip E. Bickler, Department of Anesthesia and Perioperative Care, University of California, San Francisco

Comments from NSF:

“The potential impact of this device is huge. This technology could lead to a low-cost, small-size, low-power carbon dioxide sensor. The high-sensitivity device might replace bulky and expensive NDIR (non-dispersive infrared absorption) sensors.” — Winslow Sargeant, NSF Small Business Innovation Research Program officer who oversees the Nanomix award. “This is a high-risk, high-return technology. On a larger scale, the finalized product would lower the cost of respiratory track monitoring, becoming an essential tool for intensive care units and during anesthesia.” — Winslow Sargeant

Media Contact

More Information:

http://www.nsf.govAll latest news from the category: Health and Medicine

This subject area encompasses research and studies in the field of human medicine.

Among the wide-ranging list of topics covered here are anesthesiology, anatomy, surgery, human genetics, hygiene and environmental medicine, internal medicine, neurology, pharmacology, physiology, urology and dental medicine.

Newest articles

Targeted use of enfortumab vedotin for the treatment of advanced urothelial carcinoma

New study identifies NECTIN4 amplification as a promising biomarker – Under the leadership of PD Dr. Niklas Klümper, Assistant Physician at the Department of Urology at the University Hospital Bonn…

A novel universal light-based technique

…to control valley polarization in bulk materials. An international team of researchers reports in Nature a new method that achieves valley polarization in centrosymmetric bulk materials in a non-material-specific way…

How evolution has optimised the magnetic sensor in birds

The magnetic sense of migratory birds is probably based on the protein cryptochrome 4, and a genetic study has now provided further support for this theory. A team of researchers…