New dressing for wound developed at Hebrew University promises faster and improved healing

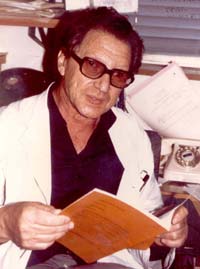

Prof. Shmuel Shoshan

A novel wound dressing made of genetically engineered human collagen that will enable faster and improved healing of injuries has been developed by researchers at the Hebrew University Faculty of Dental Medicine.

Collagen is the most abundant protein in the animal kingdom, including humans. It is the major constituent of connective tissues – tendons, skin, bones, cartilage, blood vessel walls and membranes. Collagen fibers are the “warp and woof” of these connective tissues and are responsible for keeping all the body’s organs and tissues in their correct functional structure.

There are different collagen-containing preparations on the market today made for treating wounds, for use in dentistry implants, and in cosmetics. All of them use collagen made from animal tissues, which requires specific adaptation in order to eliminate immunological rejection or to prevent microbiological infection.

The dressing developed at the Hebrew University incorporates an inner layer of genetically engineered, human recombinant collagen. This material becomes a soluble, readily enzymatically degradable molecule in the wound tissue. The molecular fragments that are thus formed have been shown to play a pivotal role in the healing process. An outer layer, also of biological origin, is provided in the wound dressing to provide initial protection prior to release of the delicate collagen layer.

Preliminary animal experiments with the new dressing have shown substantially faster and better healing, with rapid formation of new collagen fibers, than has been possible using older methods.

The new dressing is the fruit of many years of experimentation with collagen in the laboratory of Prof. Emeritus Shmuel Shoshan of the Connective Tissue Research Laboratory of the Hebrew University Faculty of Dental Medicine. Prof. Shoshan is the inventor and chief scientist of Dittekol Ltd., a company formed in cooperation with the Hebrew University’s Yissum Research Development Company, to commercialize the new wound dressing. The company is now negotiating with investors for further development.

For further information: Jerry Barach, Dept. of Media Relations, the Hebrew University, Tel: 02-588-2904

Media Contact

All latest news from the category: Health and Medicine

This subject area encompasses research and studies in the field of human medicine.

Among the wide-ranging list of topics covered here are anesthesiology, anatomy, surgery, human genetics, hygiene and environmental medicine, internal medicine, neurology, pharmacology, physiology, urology and dental medicine.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…