Comprehensive Environmental Protection in Medical Technology

Long before the terms “climate change” and “energy efficiency” were on everyone’s lips, Siemens was working hard to systematically improve the impact of its products and systems on people and the environment. This is especially true at Siemens Medical Solutions (Med).

As a result, new computed tomography systems consume 30 percent less energy, contain 80 percent less lead, and generate up to 58 percent less radiation than previous systems. And refurbished medical technology devices receive the “Proven Excellence” quality seal for their environmental compatibility. Comprehensive quality standards apply to all phases of medical technology systems, from production, to use, to refurbishment and disposal. In accordance with the comprehensive approach of the European Commission regarding integrated product policies, Siemens takes all relevant environmental aspects into account across the entire product lifecycle.

Refurbishing used systems is a critical component of the corporate philosophy: extending the lifecycle of a product saves resources. For example, used computed tomography, magnetic resonance tomography, ultrasound, radiation therapy, and radiography systems are accepted back, and then refurbished by a separate product group called Refurbished Systems (RS). Refurbishment follows a comprehensive, fivestage quality process (device selection, qualified disassembly, refurbishment process, installation, warranty against defects) with the same high standards as for new devices.

The systems then leave the factory with the “Proven Excellence” quality seal and are sold throughout the world. Economical and efficient, top class refurbished systems tailored to the customer complement the innovative product portfolio of Siemens Medical Solutions. RS thereby provides a significant contribution to the environmental initiative of Siemens AG. In addition, this comprehensive approach prevents 10,000 tons of CO2 emissions annually. The savings correspond to the energy needs of 3000 three-person households per year.

Comprehensive Environmental Protection

An lifecycle assessment has shown that the environmental impact of medical devices is significantly higher in the usage phase than the manufacturing phase. While a magnetic resonance tomography system (MRT) such as the Magnetom Avanto is in use by the customer, it consumes the majority of its lifecycle’s energy: 88 percent. Its manufacture and recycling account for the remaining twelve percent. The same is true for most other long-lasting electrical and electronic products. For this reason, Siemens relies on comprehensive environmental protection. This means the devices are designed to have as little negative environmental impact as possible – across the entire lifecycle. This includes all phases, from material selection and manufacturing, to usage, to recycling.

Award Winning: the Somatom Definition Computed Tomography System

During a cardiac examination, the Somatom Definition computed tomography system (CT) generates up to 58 percent less radiation, depending on the patient’s pulse rate, with significantly improved image quality. As a result, the examination is much safer for the patient. To generate radiation, the system requires power. The reduction is radiation dose not only protects the patient, it saves energy and helps in protecting the environment. In a defined standard examination, the CT system requires 30 percent less energy than its predecessor. Somatom Definition only contains 19 kilograms of lead, compared to 110 as in the past – a drop of more than 80 percent.

The remaining lead is required to provide radiation shielding. Through these improvements, the developers were able to reduce the environmental impact of production and establish the prerequisites for reduced energy requirements in the usage phase. The highperformance X-ray tubes in the CT system are returned, refurbished in a complicated, quality assured process, and reused as reconditioned parts. For its contribution to environmental protection with the Somatom Definition, in 2006 Med was awarded the international Siemens Environmental Prize.

Product Environmental Declarations

To inform its customers of the environmental characteristics of medical devices, Siemens has created product environmental declarations. In the future for example, prior to purchase customers will be able to evaluate the follow-up costs produced when operating Siemens medical devices. Med worked together with representatives of hospitals and leading medical technology manufacturers to determine what information the product environmental declarations had to contain. In the future, whenever a new Med product comes to market, this brochure will be published at the same time. It will provide information on materials, energy consumption, radiation intensity, spare parts consumption, and other aspects relevant for decision making. Product environmental declarations are already available for the Magnetom Avanto and Espree MRT systems, as well as the Somatom Definition CT system.

EMAS

The environmental management system of the European Union, called EMAS (Eco- Management and Audit Scheme), is the system with the world’s strictest requirements. It has been implemented voluntarily at all Siemens locations in Germany since 1996: every product and work step is audited periodically. Independent, nationally certified EMAS auditors check every year whether the environmental protection guidelines are being maintained at the production facilities. In addition, the auditors evaluate whether actual improvements have been achieved in critical environmental aspects. The environmental auditors also check the plausibility of the information in the environmental statement that is published annually. The information on environmentally-relevant activities, procedures, energy and material consumption, hazardous emissions, influence on the environmental behavior of suppliers, and actions to improve the environment thereby enjoy a special level of trust. Med is following the objective of minimizing its environmental impact internationally. The internal EH&S policy (Environmental, Health, and Safety) and the EH&S management system apply worldwide to all locations and products.

Siemens Medical Solutions of Siemens AG (NYSE: SI) is one of the world’s largest suppliers to the healthcare industry. The company is known for bringing together innovative medical technologies, healthcare information systems, management consulting, and support services, to help customers achieve tangible, sustainable, clinical and financial outcomes. Recent acquisitions in the area of in-vitro diagnostics – such as Diagnostic Products Corporation and Bayer Diagnostics – mark a significant milestone for Siemens as it becomes the first full service diagnostics company. Employing more than 41,000 people worldwide and operating in over 130 countries, Siemens Medical Solutions reported sales of 8.23 billion EUR, orders of 9.33 billion EUR and group profit of 1.06 billion EUR for fiscal 2006 (Sept. 30), according to U.S. GAAP.

Media Contact

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Laser immersion probe for smart inline monitoring of water and wastewater

A new type of laser-based immersion probe, which the Fraunhofer Institute for Laser Technology ILT in Aachen is testing as part of BMBF- and EU-funded projects with industrial partners and…

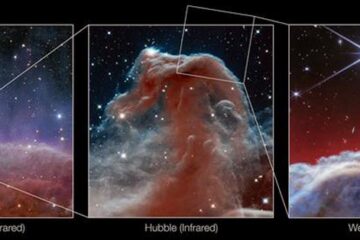

Webb captures top of iconic horsehead nebula in unprecedented detail

NASA’s James Webb Space Telescope has captured the sharpest infrared images to date of a zoomed-in portion of one of the most distinctive objects in our skies, the Horsehead Nebula….

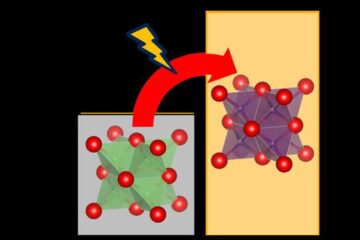

Cost-effective, high-capacity, and cyclable lithium-ion battery cathodes

Charge-recharge cycling of lithium-superrich iron oxide, a cost-effective and high-capacity cathode for new-generation lithium-ion batteries, can be greatly improved by doping with readily available mineral elements. The energy capacity and…