Laser Light in Operation for Medical Technology

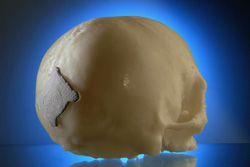

A biodegradable skull implant made out of PLA/â-TCP by means of SLM in cooperation with the KLS Martin group and the Dental Materials and Biomaterials Research (ZWBF) at the University Hospital Aachen. Fraunhofer Institute for Laser Technology ILT, Aachen<br>

In addition, the experts will be showing the professional audience processes to laser weld plastics for medical components without leaving welding seams as well as to laser polish metal.

At the IVAM joint stand H 19.1 in Hall 8a at this year’s Compamed (in Dusseldorf, Nov. 17 to 19, 2010), the Fraunhofer ILT is presenting tailor-made biodegradable implants. They were produced using Selective Laser Melting (SLM), an additive laser manufacturing process. Thanks to their interconnective pore system, these implants made of β-tricalcium phosphate enhance stromal and vascular cells’ ingrowth ability. In addition, porous implants made of a titanium alloy, manufactured using SLM, will be shown.

Another area where lasers can be used in medical technology is the polishing of metal. In this case, the laser beam melts the material surface to a depth of about 5 microns. The surface tension ensures that the fluid metal flows evenly and dries smoothed. This process developed by Fraunhofer ILT is interesting for all medical-technical components with metallic surfaces that need to have an extremely low roughness. Manufacturers can see examples of such components at the IVAM stand.

For medical-technical products made out of plastics the Fraunhofer ILT will be presenting an efficient welding process. The TransTWIST process (Transmission Welding by an Incremental Scanning Technique) allows two transparent joining partners to be connected together in an overlap by means of laser radiation without the need for additional absorbers. In contrast to conventional laser welding, expensive pretreatment steps can be omitted. The end user thus saves time and money. Thanks to the laser welding machine TransTWIST, extremely high-quality welding seams can be made, which fulfill all established requirements upon the end result as to invisible welding seams and expansion in the heat affected zone. A main area of application is in medical technology, especially microfluidics.

Contact Partners at the Fraunhofer ILT

Our experts would be glad to answer any questions you may have:

Dipl.-Ing. Christian Nüsser

Polishing

Telephone: +49 241 8906-669

christian.nuesser@ilt.fraunhofer.de

Dipl.-Ing Andrei Lucian Boglea

Microjoining

Telephone +49 241 8906-217

andrei.boglea@ilt.fraunhofer.de

Dr. Arnold Gillner

Competence Area Manager Ablating and Joining

Telephone +49 241 8906-148

arnold.gillner@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen

Germany

Tel. +49 241 8906-0

Fax. +49 241 8906-121

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

Red light therapy for repairing spinal cord injury passes milestone

Patients with spinal cord injury (SCI) could benefit from a future treatment to repair nerve connections using red and near-infrared light. The method, invented by scientists at the University of…

Insect research is revolutionized by technology

New technologies can revolutionise insect research and environmental monitoring. By using DNA, images, sounds and flight patterns analysed by AI, it’s possible to gain new insights into the world of…

X-ray satellite XMM-newton sees ‘space clover’ in a new light

Astronomers have discovered enormous circular radio features of unknown origin around some galaxies. Now, new observations of one dubbed the Cloverleaf suggest it was created by clashing groups of galaxies….