Genetic master switch sends bacteria toward ’seafood dinner’

Biologists unravel part of the mystery behind disappearance of shell material

Chitin, the Earth’s second-most abundant biological material, is a major component in the flurry of skeletal debris discarded daily by crustacean creatures in the world’s oceans. If left undisturbed, this tough insoluble material, a cousin to cellulose, would pile up on the ocean’s floor and wreak havoc with marine ecosystems. Fortunately, armies of bacteria act as chitin’s cleanup crew, and two Johns Hopkins University biologists have made a key discovery about how and when these microscopic soldiers launch their search-and-devour missions.

Writing in the Online Early Edition of “Proceedings of the National Academy of Sciences” for the week of Dec. 29, 2003, Xibing Li and Saul Roseman reported that they had found a genetic master switch that reacts to the presence of nearby chitin and sets off a biological chain reaction, causing the bacterial feast to begin. Understanding this process is important because 1011 tons of chitin (pronounced “KITE-in”) are dumped annually in the oceans, largely by tiny sea animals called copepods, which shed their shells as they grow. “If nothing happened to this debris, we’d be up to our eyeballs in chitin, and the carbon and nitrogen cycle upon which marine life depends would be gone within 50 to 75 years,” said Roseman, a professor of biology in the Kreiger School of Arts and Sciences at Johns Hopkins.

Researchers were puzzled about the disappearance of chitin because little of the material turned up in sediment on the ocean floors. Where did all of the chitin go? Then, about 70 years ago, two microbiologists determined that bacteria were quickly consuming the sinking shells and preserving the ecological balance. Since then, however, several mysteries have remained: How do the bacteria find these undersea meals? How do these microorganisms attach themselves to the chitin? How do they degrade the tough material and turn it into food?

During the past decade, Roseman and his colleagues have made several advances in answering these questions. In the new PNAS paper, Li and Roseman reported that they had identified and isolated the bacterial master switch that controls at least 50 and perhaps up to 300 other genes involved in the chitin sensing and consumption process. The biologists made their discovery by studying mutated versions of Vibrios, the ocean’s most common bacteria, which can cause illnesses such as cholera. The scientists separated and tested the mutant strains according to their ability to detect and break down chitin, then they analyzed the bacteria’s genetic structure to pinpoint the master switch.

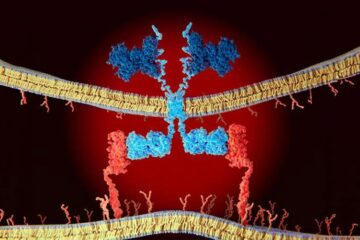

“We believe,” Roseman said, “that when the Vibrios are not in their feeding mode, this master switch remain in the ’minus’ or ’off’ position, locked in place by a binding protein. This keeps the cells from wasting energy by manufacturing proteins that won’t do them any good at that time.”

Roseman added, “When the bacteria are starving, however, they secrete an enzyme called chitinase into the water. When chitinase touches the discarded shell material, it begins breaking down chitin, releasing a partially degraded soluble form into the water. These molecules are the signals to the bacteria that chitin is nearby. Diffusing through the ocean near the bacteria, these dissolved fragments of degraded chitin bind to the binding protein and remove the ’lock,’ allowing the master switch to move into a ’plus’ or ’on’ position.”

When the switch is on, the bacteria’s genes get to work, moving the organisms along the trail of partially degraded chitin back to its source material, like a hungry traveler following the aroma of hot food to a roadside restaurant. In the ocean, the bacteria follow a gradient stream of higher and higher concentrations of dissolved degraded chitin until they reach the solid shell material. The bacteria then latch on and begin their feast.

“The master switch gene appears to be the key to this complex feeding process,” said Li, an associate research scientist in the Department of Biology and lead author of the new paper. “This gives us a better understanding of the microscopic processes that keep our oceans from being overwhelmed by biological debris from sea creatures.”

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…