Detecting H1N1 faster than ever using Omics SmartAmp technology

As a part of emergency government research aimed at addressing this need, RIKEN and University of Tokyo, are developing an H1N1 detection technique based on its SmartAmp technology.

With the number of novel influenza A (H1N1) cases increasing in countries around the world, the rapid spread of the virus has triggered worldwide alarm. There is a pressing need at medical institutions for methods to detect whether individuals are infected with the virus in order to effectively slow its spread.

As a part of emergency government research aimed at addressing this need, the RIKEN Omics Science Center (OSC), in cooperation with the Institute of Medical Science at the University of Tokyo, is developing an H1N1 detection technique based on its SmartAmp technology.

The SmartAmp (Smart Amplification Process) reduces the single nucleotide polymorphism (SNP) analysis time to just half an hour, and the precise results thus produced allow genetic diagnosis to be carried out immediately upon initial consultation. Using this technology, OSC has developed methods for detecting the regular seasonal influenza A virus, the H3N2 virus, and the susceptibility of these viruses to Tamiflu treatment. Most laboratories continue to use the RT-PCR system, which for H1N1 necessitates reverse transcription in order to convert RNA into DNA (H1N1 is an RNA virus). The SmartAmp approach carries out this step in parallel with DNA amplification. The time and effort required for the new technique is thus roughly the same as in the conventional SmartAmp process.

OSC researchers are currently applying SmartAmp for diagnosis of the H1N1 virus, as well as developing reagents for virus detection and optimizing the conditions for the reagents. Once optimization is complete, tests will be performed on actual samples from patients at the Osaka Prefectural Institute of Public Health. In cooperation with the Infectious Disease Surveillance Center and the International Medical Center of Japan, the goal is to deploy the technique to clinics within the next six months.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

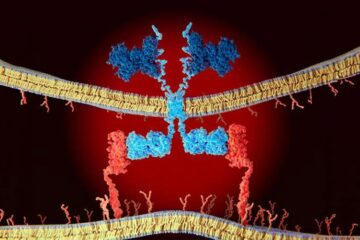

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…