Algae for Your Tank?

The available amount of fossil fuels is limited and their combustion in vehicle motors increases atmospheric CO2 levels. The generation of fuels from biomass as an alternative is on the rise. In the journal Angewandte Chemie, Johannes A. Lercher and his team at the Technische Universität München have now introduced a new catalytic process that allows the effective conversion of biopetroleum from microalgae into diesel fuels.

Plant oils from sources such as soybean and rapeseed are promising starting materials for the production of biofuels. Microalgae are an interesting alternative to these conventional oil-containing crops. Microalgae are individual cells or short chains of cells from algae freely moving through water. They occur in nearly any pool of water and can readily be cultivated. “They have a number of advantages over oil-containing agricultural products,” explains Lercher. “They grow significantly faster than land-based biomass, have a high triglyceride content, and, unlike the terrestrial cultivation of oilseed plants, their use for fuel production does not compete with food production.”

Previously known methods for refining oil from microalgae suffer from various disadvantages. The resulting fuel either has too high an oxygen content and poor flow at low temperatures, or a sulfur-containing catalyst may contaminate the product. However, other catalysts are still not efficient enough. The Munich scientists now propose a new process, for which they have developed a novel catalyst: nickel on a porous support made of zeolite HBeta. They have used this to achieve the conversion of raw, untreated algae oil under mild conditions (260 °C, 40 bar hydrogen pressure). Says Lercher: “The products are diesel-range saturated hydrocarbons that are suitable for use as high-grade fuels for vehicles.”

The oil produced by the microalgae is mainly composed of neutral lipids, such as mono-, di-, and triglycerides with unsaturated C18 fatty acids as the primary component (88 %). After an eight-hour reaction, the researchers obtain 78 % liquid alkanes with octadecane (C18) as the primary component. The main gas-phase side products are propane and methane.

Analysis of the reaction mechanism shows that this is a cascade reaction. First the double bonds of the unsaturated fatty acid chains of the triglycerides are saturated by hydrogen. Then, the now saturated fatty acids take up hydrogen and are split from their glycerin component, which reacts to form propane. In the final step, the acid groups in the fatty acids are reduced stepwise to the corresponding alkane.

About the Author

Dr. Johannes A. Lercher is Professor of Chemical Technology at the TU München, Germany, Director of the Institute for Integrated Catalysis at the Pacific Northwest National Laboratory and Vice President of the German Catalysis Society. His research activities are focused on oxide and molecular-sieve-based sorption and catalysis, the activation and functionalization of hydrocarbons, the deconstruction and defunctionalization of biomass, catalyst design, and the in situ characterization of catalytic processes.

Author: Johannes A. Lercher, Technische Universität München (Germany), http://www.tc2.ch.tum.de/

Title: Towards Quantitative Conversion of Microalgae Oil to Diesel-Range Alkanes with Bifunctional Catalysts

Angewandte Chemie International Edition, Permalink to the article: http://dx.doi.org/10.1002/anie.201106243

Media Contact

More Information:

http://www.tc2.ch.tum.de/All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

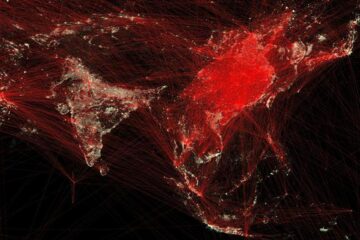

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

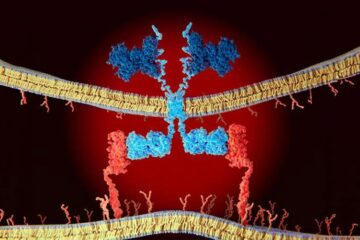

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…