Ultra-fast, the bionic arm can catch objects on the fly

Photos: ©EPFL

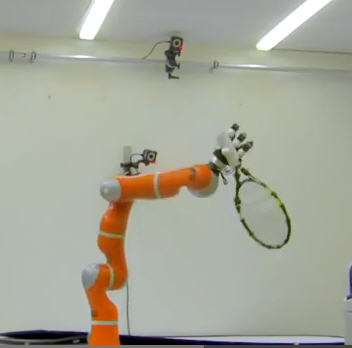

With its palm open, the robot is completely motionless. A split second later, it suddenly unwinds and catches all sorts of flying objects thrown in its direction -a tennis racket, a ball, a bottle-. This arm measures about 1.5 meters long and keeps an upright position.

It has three joints and a sophisticated hand with four fingers. It was programmed at the Learning Algorithms and Systems Laboratory at EPFL (LASA) and designed to test robotic solutions for capturing moving objects. It is unique, as it has the ability to catch projectiles of various irregular shapes in less than five hundredths of a second. This invention is described in an article published today by IEEE transactions on robotics, the first journal in the field.

“Increasingly present in our daily lives and used to perform various tasks, robots will be able to either catch or dodge complex objects in full-motion, said Aude Billard, head of LASA. Not only do we need machines able to react on the spot, but also to predict the moving object's dynamics and generate a movement in the opposite direction.”

This robotic arm already has a very real potential application in space. It has been associated to the Clean- mE project carried out by the Swiss Space Center at EPFL, which aims to develop technologies for the recovery and disposal of space debris orbiting around Earth. Fitted on a satellite, the arm would have the task of catching flying debris, whose dynamics are only partially known. Hence, the robot will not be able to work out such dynamics with precision until in space, by observing the movement of the approaching objects.

Imitation

The ability to catch flying things requires the integration of several parameters and reacting to unforeseen events in record time. “Today's machines are often pre-programmed and cannot quickly assimilate data changes, added Aude Billard. Consequently, their only choice is to recalculate the trajectories, which requires too much time from them in situations in which every fraction of a second can be decisive.”

To obtain the desired speed and adaptability, LASA researchers were inspired by the way humans themselves learn: by imitation and trial and error. This technique, called Programming by demonstration, does not give specific directions to the robot. Instead, it shows examples of possible trajectories to it. It consists in manually guiding the arm to the projected target and repeating this exercise several times.

The research was conducted with a ball, an empty bottle, a half full bottle, a hammer and a tennis racket. These five common objects were selected because they offer a varied range of situations in which the part of the object that the robot has to catch (the handle of the racket, for example) does not correspond to its center of gravity. The case of the bottle even offers an additional challenge since its center of gravity moves several times during its trajectory. When projected into the air, all these items will make even more complex movements, often involving several axes. As a result, when the moving objects are submitted to the robot's abilities, the outcomes turn out quite interesting.

In the first learning phase, objects are thrown several times in the robot's direction. Through a series of cameras located all around it, the robot creates a model for the objects' kinetics based on their trajectories, speeds and rotational movement. Scientists translate it into an equation which then allows the robot to position itself very quickly in the right direction whenever an object is thrown. During the few milliseconds of the approach, the machine refines and corrects the trajectory for a real-time and high precision capture. This efficiency is further enhanced by the development of controllers that couple and synchronize the movements of the hand and fingers.

Press material:

Press Kit (broadcast video & broll, pictures): http://bit.ly/1lRDvIU

Youtube video: http://bit.ly/1lRBrAA

Photos: ©EPFL

Researchers contacts:

Aude Billard, Learning algorithms and systems Laboratory EPFL: email aude.billard@epfl.ch, tel: +41 21 693 54 64.

Ashwini Shukla, assistant-doctorant, LASA: email ashwini.shukla@epfl.ch, tel: +41 21 693 69 47, cell +41 78 693 66 57.

Seungsu Kim, assistant-doctorant, LASA: email seungsu.kim@epfl.ch, tel: +41 21 69 35463, cell +41 79 261 65 78.

Media contact:

Sarah Perrin, scientific editor at EPFL: email sarah.perrin@epfl.ch, tel: +41 21 693 21 07.

Hillary sanctuary, EPFL Media Relations, Hillary.sanctuary@epfl.ch, +41 21 693 70 22, cell: +41 79 703 48 09

Media Contact

All latest news from the category: Interdisciplinary Research

News and developments from the field of interdisciplinary research.

Among other topics, you can find stimulating reports and articles related to microsystems, emotions research, futures research and stratospheric research.

Newest articles

Sea slugs inspire highly stretchable biomedical sensor

USC Viterbi School of Engineering researcher Hangbo Zhao presents findings on highly stretchable and customizable microneedles for application in fields including neuroscience, tissue engineering, and wearable bioelectronics. The revolution in…

Twisting and binding matter waves with photons in a cavity

Precisely measuring the energy states of individual atoms has been a historical challenge for physicists due to atomic recoil. When an atom interacts with a photon, the atom “recoils” in…

Nanotubes, nanoparticles, and antibodies detect tiny amounts of fentanyl

New sensor is six orders of magnitude more sensitive than the next best thing. A research team at Pitt led by Alexander Star, a chemistry professor in the Kenneth P. Dietrich…