University of Portsmouth develops new aircraft component testing method to make air travel safer and cheaper

Professor Jie Tong, an aerospace mechanics expert from the University’s Department of Mechanical and Design Engineering, is leading the international team of experts with funding from the Royal Society.

The team’s mission is to develop state-of-the-art computer modelling programs that will reveal how aircraft components react under the stresses of flying.

The existing life prediction method involves expensive mechanical testing – one of the reasons why it costs so much to buy a plane ticket.

In particular, the researchers are looking at small cracks inherent in metal components in aircraft engines. These cracks grow and change over time. This process is known as metal fatigue or ‘fatigue crack growth’.

Metal fatigue in aeroplane engines is not a common cause of crashes – pilot error is a larger one – but it has resulted in a number of incidents in the past, most notably the 1989 United Airlines crash in the United States when a passenger plane cartwheeled across the tarmac while trying to land.

Investigators later found a piece of metal holding the fan blades had shattered, ruining the DC-10’s hydraulics. The accident killed 112 people.

“In any aircraft journey the parts of the engine go through a complex combination of stresses and vibrations. We need to know how the inherent cracks in the metal are going to be affected,” Professor Tong explained.

“The safety of aircraft depends on engineers knowing when the cracks are going to become a problem so that plans can be made to replace components during regular inspection cycles. The scheduling of these inspections critically depends on the precise knowledge of crack growth mechanisms and growth rate.”

Professor Tong said the research team would use novel experimental and computational methods to create a comprehensive computer modelling program that will show in detail how the components react under stress.

The Royal Society funding will allow the Portsmouth team to join forces with materials scientists from the University of Siegen in Germany.

“We will be working with the Siegen scientists, using a powerful transmission microscope (TEM) to examine the complex dislocation structure and other microscopic changes in the components caused by damage,” Professor Tong said.

“We will then take this information and create a mathematical model to accurately predict the rate of fatigue crack growth.

“This work will not only improve air safety, but also reduce the maintenance cost – currently running into billions of dollars worldwide – which means cheaper and safer air travel for all.”

The University of Portsmouth has a strong track record in aerospace mechanics. Researchers at the Department of Mechanical and Design Engineering have been working with Rolls Royce – the world’s leading manufacturer of aeroengines – for more than 30 years.

Media Contact

More Information:

http://www.port.ac.ukAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

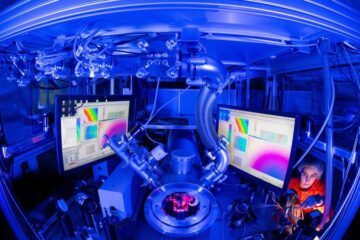

Caution, hot surface!

An international research team from the University of Jena and the Helmholtz Institute Jena are demystifying the mechanisms by which high-intensity laser pulses produce plasma on the surface of solids….

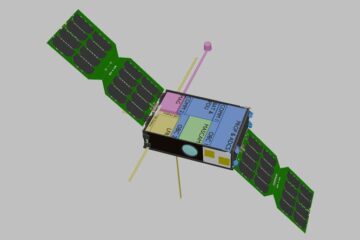

Exploring the Asteroid Apophis With Small Satellites

In five years’ time, a large asteroid will fly very close to Earth – a unique opportunity to study it. Concepts for a national German small satellite mission are being…

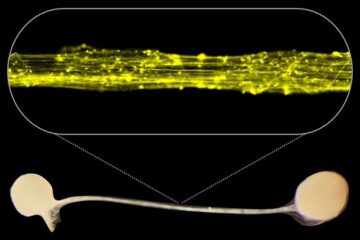

First model of the brain’s information highways developed

Our human brain is not only bigger and contains more neurons than the brains of other species, but it is also connected in a special pattern: Thick bundles of neurons…