Siemens develops new electric arc furnace for efficient electric steel production

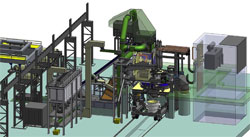

Simetal Quantum EAF from Siemens: Computer-animated general view of the plant.

The Simetal EAF Quantum electric arc furnace from Siemens combines tried-and-tested elements of preheating furnace technology with a number of new developments. These include a new scrap charging process, an efficient preheating system, a new tilting concept for the lower shell, and an optimized tapping system.

A reference furnace with a tapping weight of 100 tons achieves an output of 1.35 million tons of crude steel per year with a tap-to-tap time of 33 minutes. The electrical energy consumption, at just 280 kilowatt-hours per ton, is considerably lower than that of a conventional electric arc furnace. Coupled with a lower consumption of electrodes and oxygen, this results in a total specific conversion cost advantage of around 20 percent.

The Simetal EAF Quantum is designed as a shaft furnace. Unlike a conventional electric arc furnace, it is not necessary to raise the roof and retract the electrodes in order to charge the furnace. The other benefit of charging via a shaft is that the scrap is preheated by the offgas of the melting process, which significantly reduces energy requirements.

The combination of a fixed shaft structure and a moveable lower shell provides enhanced air-tightness and minimizes the ingress of atmospheric air. In combination with an automated offgas stream redirection system and a special hood to capture dust and offgases during charging, process emissions are considerably lower in the steel plant. This reduces the cost and size of the dedusting system and the canopy installation substantially.

The electric arc furnace is charged with scrap by means of an elevator system. A hopper transports the scrap from a charging station in the scrap yard to the shaft, eliminating the need for cranes and baskets. A defined duty cycle or a precise charging time can be specified and, if required, the charging process can also be fully automated. The shaft has a trapezoidal shape and is equipped with a retaining system. This facilitates better distribution of the scrap and improves direction of the offgas to optimize heat transfer. After the scrap has been preheated, the fingers of the retaining system are opened, and the scrap passes into the melting bath which has a maximum capacity of 70 tons. The fingers can then be closed immediately so that the next scrap charge can be fed in and preheated.

Melting the scrap in a large melting bath allows pure flat bath operation. This is also assisted by efficient preheating of the following scrap charge. In conjunction with a patented, slag-free tapping system, charging, tapping and taphole refilling can all be done under power on. This leads to extremely short tap-to-tap times and high productivity. The transfer of heat from the melting bath into the preheated scrap, and the homogenization of the melt are assisted by a bottom stirring system with argon. Supplying electrical energy continuously in flat bath operation not only improves productivity but also avoids net disturbances, such as flicker. Compared to conventional furnaces with the same productivity, the processing concept using flat bath operation also enables a lower-powered furnace transformer to be installed, which reduces investment costs.

The complete roof-shaft structure is a fixed installation, the furnace tapping and deslagging movements are made by the furnace shell only. The shell is installed on a base frame with cylinders and guides and can be tilted to both the tapping and slag side. The portal with the electrode lifting system and the lances is not tilting, but only swinging out for electrode slipping and fast roof center piece exchange. Heavy stress from furnace tilting with all its consequences on support and bearing, high current cables and gantry is not existent. The furnace shell can be easily moved and transported with the ladle car for easy maintenance work and fast shell exchange. Oxygen and coal injectors are installed in the roof only, minimizing the installations and pipework required on the furnace shell.

Further information about solutions for steel works, rolling mills and processing lines is available at: http://www.siemens.com/metals

Simetal Quantum EAF from Siemens: Computer-animated general view of the plant.

The Siemens Industry Sector (Erlangen, Germany) is the worldwide leading supplier of environmentally friendly production, transportation, building and lighting technologies. With integrated automation technologies and comprehensive industry-specific solutions, Siemens increases the productivity, efficiency and flexibility of its customers in the fields of industry and infrastructure. The Sector consists of six divisions: Building Technologies, Drive Technologies, Industry Automation, Industry Solutions, Mobility and Osram. With around 204,000 employees worldwide (September 30), Siemens Industry achieved in fiscal year 2010 total sales of approximately €34.9 billion. www.siemens.com/industry

The Siemens Industry Solutions Division (Erlangen, Germany) is one of the world's leading solution and service providers for industrial and infrastructure facilities comprising the business activities of Siemens VAI Metals Technologies, Water Technologies and Industrial Technologies. Activities include engineering and installation, operation and service for the entire life cycle. A wide-ranging portfolio of environmental solutions helps industrial companies to use energy, water and equipment efficiently, reduce emissions and comply with environmental guidelines. With around 29,000 employees worldwide (September 30), Siemens Industry Solutions posted sales of €6.0 billion in fiscal year 2010. www.siemens.com/industry-solutions

Media Contact

More Information:

http://www.siemens.com/metalsAll latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…