Quantity and Quality: Novel Sensor Module Ensures Efficient Production

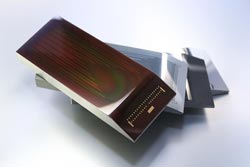

Layer by layer: The production steps of thin film sensor technology. © Fraunhofer IST<br>

Defects, especially fractures and wrinkles, slow down production processes and increase the reject rate when forming mass products, e. g. during deep-drawing of automotive parts or the manufacture of prototypes.

Fraunhofer researchers have developed a multifunctional thin film system which is located directly in the main load zones and allows for a sensitive and highly dynamic monitoring of the process. A variety of sensor modules will be presented from April 8 – 12, 2013 at Hannover Messe (hall 3, booth D25 and hall 2, booth D18).

There is almost no room for extras where stress in forming processes is at its highest level. Here, precision is the keyword. Therefore sensor systems that monitor the process are often located far from the critical range of forming tools. Researchers of the Fraunhofer Institute for Surface Engineering and Thin Films develop multifunctional sensor modules that are customized for the respective system and incorporated in the main load zones free of play, thus making a long-term stable acquisition of relevant process parameters possible.

The main part of the thin film sensor system is the DiaForce® layer – an amorphous hydrocarbon coating developed at Fraunhofer IST. The layer combines tribological stability with piezoresistive properties so that the sensor can measure forces directly in the main load zones without suffering from wear. Online monitoring, for example of the draw-in movement of sheet metal during deep-drawing processes, and accurate information acquisition from direct contact with the sheet become possible with the DiaForce® layer.

The sensor module can be applied in a variety of fields: Not only deep-drawing systems but also die-cutting systems are important application areas. Here, the module measures the cutting forces in direct contact with the punch. The thin film sensor system offers maximum flexibility when it is incorporated in washers and, in this form, can be built into virtually any system geometry without much effort, ensuring long-term stable data acquisition and monitoring of the production process.

Press contact: Dr. Simone Kondruweit | Elena Dröge

Fraunhofer Institute for Surface Engineering and Thin Films IST | Phone +49 531 2155-536 | elena.droege@ist.fraunhofer.de

Bienroder Weg 54 E | 38108 Braunschweig | info@ist.fraunhofer.de

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

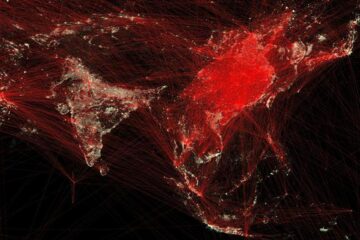

Economies take off with new airports

A global study by an SUTD researcher in collaboration with scientists from Japan explores the economic benefits of airport investment in emerging economies using nighttime satellite imagery. Be it for…

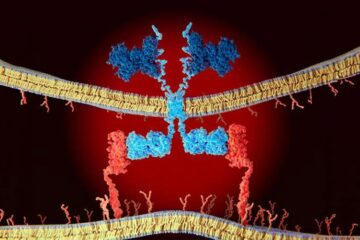

CAR T–cell immunotherapy targets

Pan-cancer analysis uncovers a new class of promising CAR T–cell immunotherapy targets. Scientists at St. Jude Children’s Research Hospital found 156 potential CAR targets across the brain and solid tumors,…

Stony coral tissue loss disease

… is shifting the ecological balance of Caribbean reefs. The outbreak of a deadly disease called stony coral tissue loss disease is destroying susceptible species of coral in the Caribbean…