Controllers enhanced by Profibus, Profinet and telecommunication services

New CPU firmware enables communication with Profinet IO devices. With two new communication modules, the Simatic S7-1200 can be operated as a Profibus master or slave. Three new telecommunication components are available to users when they want to access the controller remotely from a PC or programming device.

The new firmware version 2.0 for the Simatic S7-1200 CPUs has Profinet IO controller functionality and thus implements communication with Profinet IO devices. Thanks to the integral Web server with user-defined Web pages, users can call up CPU information and process data using a standard Web browser. Data archiving is integrated, allowing data from the user program to also be archived during runtime.

There are two new communication modules for connecting the Simatic S7-1200 controllers to Profibus. The Profibus DP master module CM 1243-5 enables the connection of up to sixteen DP slaves, such as Simatic ET 200 distributed I/O modules. S7 and PG/OP communication with other controllers, as well as with HMI (human machine interface) devices and programming devices, is also supported. With the CM 1242-5, the Simatic S7-1200 can be operated as a Profibus DP slave and connected to any Profibus DP master. Both communication modules are simply connected via the S7-1200 backplane bus to the left of the CPU.

The new modules CP 1242-7, TeleService Adapter IE Basic and TeleService Module GSM allow plant operators remote access to Simatic S7-1200 controllers. Distributed stations equipped with Simatic S7-1200 can be monitored, diagnosed, maintained and controlled cost-effectively. The CP 1242-7 is simply connected via the backplane bus of the Simatic-S7-1200 as a GSM/GPRS interface and used for telecontrol. The TeleService Adapter IE Basic and the TeleService Module GSM are available for remote maintenance and diagnostics (teleservice). To use the new telecommunication services, users enter into a standard SIM card contract or a special M2M (machine-to-machine) contract. They then have remote access to the controller using a programming device or PC equipped with the Step V11 engineering software and Internet access. Thanks to wireless access, users are able to detect and correct local faults on-site in good time from a central location.

The Siemens Industry Sector (Erlangen, Germany) is the world's leading supplier of environmentally friendly production, transportation, building and lighting technologies. With integrated automation technologies and comprehensive industry-specific solutions, Siemens increases the productivity, efficiency and flexibility of its customers in the fields of industry and infrastructure. The Sector consists of six Divisions: Building Technologies, Drive Technologies, Industry Automation, Industry Solutions, Mobility and Osram. With around 207,000 employees worldwide Siemens Industry posted sales of about EUR35 billion in fiscal year 2009. http://www.siemens.com/industry

The Siemens Industry Automation Division (Nuremberg, Germany) is a global leader in the fields of automation systems, industrial controls and industrial software. Its portfolio ranges from standard products for the manufacturing and process industries to solutions for whole industrial sectors that encompass the automation of entire automobile production facilities and chemical plants. As a leading software supplier, Industry Automation optimizes the entire value added chain of manufacturers – from product design and development to production, sales and a wide range of maintenance services. With around 39,000 employees worldwide (September 30), Siemens Industry Automation achieved sales of €7.0 billion in fiscal year 2009. www.siemens.com/industryautomation

Reference Number: IIA2010112513e

Media Contact

More Information:

http://www.siemens.com/simatic-s7-1200All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

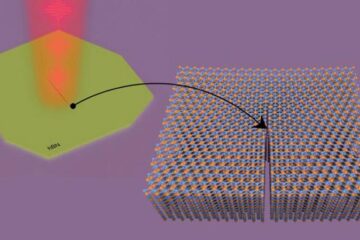

Columbia researchers “unzip” 2D materials with lasers

The new technique can modify the nanostructure of bulk and 2D crystals without a cleanroom or expensive etching equipment. In a new paper published on May 1 in the journal…

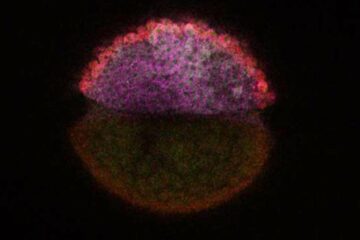

Decoding development: mRNA’s role in embryo formation

A new study at Hebrew University reveals insights into mRNA regulation during embryonic development. The study combines single-cell RNA-Seq and metabolic labeling in zebrafish embryos, distinguishing between newly-transcribed and pre-existing…

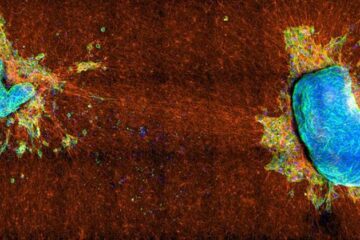

Study sheds light on cancer cell ‘tug-of-war’

How cancer cells tug against each other determines whether they can migrate elsewhere in the body. Understanding how cancerous cells spread from a primary tumor is important for any number…