Siemens is trendsetter with process bus for protection devices in power transmission grids

The process bus has advantages especially in the high-voltage area where protection devices are normally installed at some distance from the instrument transformers. The merging units can be mounted near the instrument transformers and can be connected to the protection devices via fiber-optic Ethernet connections instead of via copper cable as at present. This not only reduces cabling and maintenance costs but cuts costs for installation and for the actual cable. The process bus technology also increases the flexibility of the protection system.

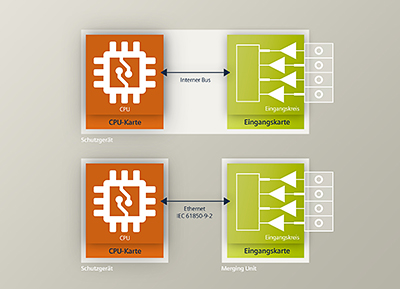

Without the process bus, the protection devices are connected to the instrument transformers directly with copper cables. Since this has to be done for every single signal, it increases the amount of wiring necessary in the switching station. This can be reduced by using process bus technology. With classic protection devices the process data is measured directly in the protection device via a special input card. This analog input card consists of an input circuit, an analog-digital converter and a bus connection to the CPU. All these connection terminals are located inside the device and are manufacturer-specific.

With Siemens process bus technology, the input card is separated from the CPU of the protection device and the range of the bus is extended from a few centimeters to as much as two kilometers. This separation creates two devices. The existing analog input card and the bus connection form the merging unit which can now be installed close to the instrument transformer and thanks to the process bus well away from the protection device. The protection device has been fitted with a process bus input, and the former input card is no longer used. The communications interface between merging unit and protection device has been standardized in IEC 61850-9-2 in order to create the necessary interoperability.

Process bus technology allows the merging unit to be installed close to the instrument transformer, which reduces the length of the copper connecting cable between the transformer and merging unit. The merging unit is equipped on the output side with fiber-optic Ethernet ports and the connection between merging unit and protection device is provided by fiber-optic cables. Instead of wiring the analog transformer inputs to the protection device as in the past, with the process bus the merging unit is connected close to the transformer, and the collected data distributed from there via Ethernet.

The process bus also increases the flexibility of the protection system. Using Ethernet as the communication channel, telegrams from more than just one protection device can be received and processed by the same merging unit without the need for additional cabling. This additionally reduces the cabling work necessary in the entire system. Expansion of the system is also possible without great cost and effort. An additional protection device can be installed in the switching station by inserting a cable to the Ethernet communications interface. Since the added protection device is usually at the same location as the other devices, the process bus infrastructure is already in place there. This means that the only cabling required for the new device is for connecting it to the system.

Automation of switchgear in accordance with IEC 61850-8-1 is state of the art today. The binary data that used to be transmitted between protection devices via directly wired, discrete binary inputs and outputs is now replaced by Goose messages (Generic object oriented substation events). This technology already reduces the number of copper cables and is widely used. The success of Goose messages in replacing copper cables has shown how successfully Ethernet technologies can improve the effectiveness and reliability of energy automation systems. The reduction of copper cables, and higher system reliability and security at substations will also help pave the way for the process bus.

Energy-efficient, eco-friendly solutions for setting up intelligent power supply networks (Smart Grids) and the associated service are part of Siemens' Environmental Portfolio. Around 43 percent of its total revenue stems from green products and solutions. That makes Siemens one of the world's leading providers of eco-friendly technology.

The Siemens Infrastructure & Cities Sector (Munich, Germany), with approximately 90,000 employees, focuses on sustainable and intelligent infrastructure technologies. Its offering includes products, systems and solutions for intelligent traffic management, rail-bound transportation, smart grids, power distribution, energy efficient buildings, and safety and security. The Sector comprises the divisions Building Technologies, Low and Medium Voltage, Mobility and Logistics, Rail Systems and Smart Grid. For more information please visit http://www.siemens.com/infrastructure-cities

The Siemens Smart Grid Division (Nuremberg, Germany) offers power providers, network operators, industrial enterprises and cities an end-to-end portfolio with products and solutions to develop intelligent energy networks. Smart Grids enable a bidirectional flow of energy and information. They are required for the integration of more renewable energy sources in the network. In addition, power providers can run their plants more efficiently with data gained from Smart Grids. Software solutions that analyze data from Smart Grids will continuously gain importance. Thereby, the division uses in-house developments in addition to systems from software partners. For further information please see: http://www.siemens.com/smartgrid

Reference Number: ICSG201408051e

Contact

Mr. Dietrich Biester

Smart Grid Division

Siemens AG

Gugelstr. 65

90459 Nuremberg

Germany

Tel: +49 (911) 433-2653

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…