Twisting the light away

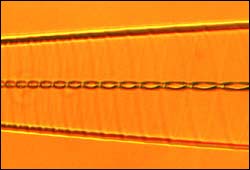

Tapered chiral optical fiber created by Chiral Photonics. Fiber is less than 100 millionths of a meter in diameter.Credit: Chiral Photonics, Inc.; National Science Foundation <br>

Add a deceptively simple twist to a tiny fiber of glass and you get a versatile new class of optical devices to filter light; sense changes in temperature, pressure or other environmental factors; or transmit information via powerful, inexpensive lasers, according to researchers at Chiral Photonics Inc. of Clifton, N.J. Writing in the July 2 issue of Science, the company describes a new class of devices called chiral gratings that were developed with support from the Advanced Technology Program at the National Institute of Standards and Technology (NIST) and from the National Science Foundation.

If the finely controlled process for making the glass fibers can be successfully scaled up to production levels, the company hopes to manufacture communications lasers, for example, that are three times more efficient than today’s semiconductor lasers at about a fifth the cost.

Conventional optical fibers have a core of round cross-section, like a strand of spaghetti, but if they are made thin and flat instead, like linguine, they can be twisted into a spiral or double-helix shape. Then something remarkable happens, according to the Chiral Photonics research team. The degree of twist in the fiber acts like a selective filter allowing light pulses with certain wavelengths (colors) or orientations (polarization) to pass through, while scattering everything else.

A gentle twist and polarized light is directed out into the fiber’s cladding, which can be tailored to capture particular wavelengths based on the external environment such as pressure, temperature or other factors. Twist harder, about one rotation per every 10 microns of length, and the fiber becomes a polarizing filter, scattering all the photons except those with a selected polarization. An even tighter twist of one rotation per wavelength and the fiber becomes a highly selective mirror, reflecting back only light of a precise wavelength–an effect that can be used for a small, powerful and inexpensive fiber-optic laser.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…