New Class of Nanoparticle Brings Cheaper, Lighter Solar Cells Outdoors

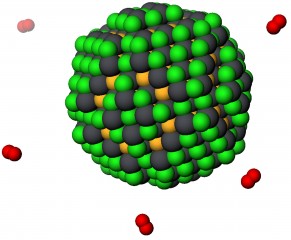

Diagram of a quantum dot. University of Toronto

Researchers in the University of Toronto’s Edward S. Rogers Sr. Department of Electrical & Computer Engineering have designed and tested a new class of solar-sensitive nanoparticle that outshines the current state of the art employing this new class of technology.

This new form of solid, stable light-sensitive nanoparticles, called colloidal quantum dots, could lead to cheaper and more flexible solar cells, as well as better gas sensors, infrared lasers, infrared light emitting diodes and more. The work, led by post-doctoral researcher Zhijun Ning and Professor Ted Sargent, was published this week in Nature Materials.

Collecting sunlight using these tiny colloidal quantum dots depends on two types of semiconductors: n-type, which are rich in electrons; and p-type, which are poor in electrons. The problem? When exposed to the air, n-type materials bind to oxygen atoms, give up their electrons, and turn into p-type. Ning and colleagues modelled and demonstrated a new colloidal quantum dot n-type material that does not bind oxygen when exposed to air.

Maintaining stable n- and p-type layers simultaneously not only boosts the efficiency of light absorption, it opens up a world of new optoelectronic devices that capitalize on the best properties of both light and electricity. For the average person, this means more sophisticated weather satellites, remote controllers, satellite communication, or pollution detectors.

“This is a material innovation, that’s the first part, and with this new material we can build new device structures,” said Ning. “Iodide is almost a perfect ligand for these quantum solar cells with both high efficiency and air stability—no one has shown that before.”

Ning’s new hybrid n- and p-type material achieved solar power conversion efficiency up to eight per cent—among the best results reported to date.

But improved performance is just a start for this new quantum-dot-based solar cell architecture. The powerful little dots could be mixed into inks and painted or printed onto thin, flexible surfaces, such as roofing shingles, dramatically lowering the cost and accessibility of solar power for millions of people.

“The field of colloidal quantum dot photovoltaics requires continued improvement in absolute performance, or power conversion efficiency,” said Sargent. “The field has moved fast, and keeps moving fast, but we need to work toward bringing performance to commercially compelling levels.”

This research was conducted in collaboration with Dalhousie University, King Abdullah University of Science and Technology and Huazhong University of Science and Technology.

Media contact:

Marit Mitchell

Senior Communications Officer

The Edward S. Rogers Sr. Department of Electrical & Computer Engineering

University of Toronto

416-978-7997; marit.mitchell@utoronto.ca

Media Contact

More Information:

http://www.utoronto.caAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Red light therapy for repairing spinal cord injury passes milestone

Patients with spinal cord injury (SCI) could benefit from a future treatment to repair nerve connections using red and near-infrared light. The method, invented by scientists at the University of…

Insect research is revolutionized by technology

New technologies can revolutionise insect research and environmental monitoring. By using DNA, images, sounds and flight patterns analysed by AI, it’s possible to gain new insights into the world of…

X-ray satellite XMM-newton sees ‘space clover’ in a new light

Astronomers have discovered enormous circular radio features of unknown origin around some galaxies. Now, new observations of one dubbed the Cloverleaf suggest it was created by clashing groups of galaxies….